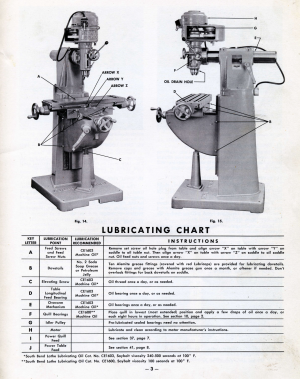

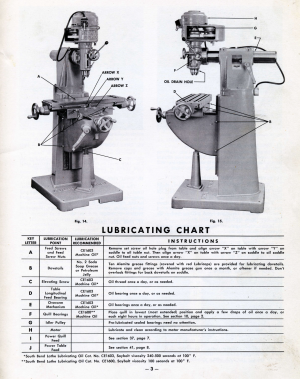

I have a few related questions relating to the correct lubrication of South Bend Vertical Mill:

1) The South Bend Lubiracting Chart (attached) says to use "No 2 Soda Soap Grease or Petroleum Jelly" for the dovetails/ways. I know that for Bridgeports, using grease is a big no-no, and they recommend oil. I know this is an old manual, but why grease? I am thinking of using ISO 68 way oil, Mobile Vactra #2, which I use for my Clausing Lathe ways; thoughts?

2) For CE1603 for the screws, table feed bearings, and overarm, I believe again, an ISO68, like Mobile Vactra #2 is a current replacement?

3) For the quill bearings, SB recommended CE1600. Is Mobile Velocite No.10 a proper replacement?

Thanks for the help!!!!

1) The South Bend Lubiracting Chart (attached) says to use "No 2 Soda Soap Grease or Petroleum Jelly" for the dovetails/ways. I know that for Bridgeports, using grease is a big no-no, and they recommend oil. I know this is an old manual, but why grease? I am thinking of using ISO 68 way oil, Mobile Vactra #2, which I use for my Clausing Lathe ways; thoughts?

2) For CE1603 for the screws, table feed bearings, and overarm, I believe again, an ISO68, like Mobile Vactra #2 is a current replacement?

3) For the quill bearings, SB recommended CE1600. Is Mobile Velocite No.10 a proper replacement?

Thanks for the help!!!!

Last edited: