Hello all,

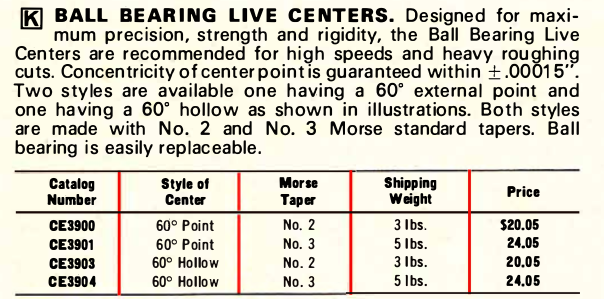

I have an SB Model-A that is has been sitting for some 50ish years but is in virtually pristine condition. It's remarkable. Anyhow, I'm in the process of getting it all spiffed up. Everything is original, chuck, tail stock live center etc. The grease in the tail stock is kind of gritting feeling from sitting around so long so I'm trying to disassemble it. It's a MLC-100NR. I removed the back set screw and the threaded plug that essentially increases or decreases the amount of "live" to the center itself. I have no clue how to get that center out of there though and I don't want to risk pressing it out. Does anyone know how this thing comes apart? I'm stumped. Maybe I should just soak it in some solvent to remove all the old grease and then try to repack it through the grease nipple? Suggestions?

I have an SB Model-A that is has been sitting for some 50ish years but is in virtually pristine condition. It's remarkable. Anyhow, I'm in the process of getting it all spiffed up. Everything is original, chuck, tail stock live center etc. The grease in the tail stock is kind of gritting feeling from sitting around so long so I'm trying to disassemble it. It's a MLC-100NR. I removed the back set screw and the threaded plug that essentially increases or decreases the amount of "live" to the center itself. I have no clue how to get that center out of there though and I don't want to risk pressing it out. Does anyone know how this thing comes apart? I'm stumped. Maybe I should just soak it in some solvent to remove all the old grease and then try to repack it through the grease nipple? Suggestions?