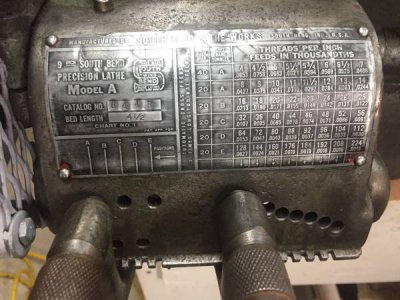

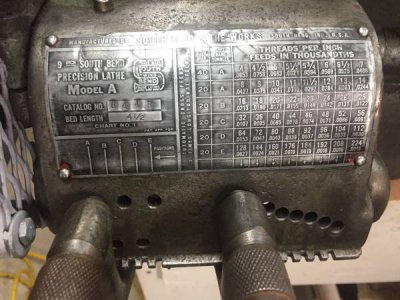

As far as usability the way it is, depends on what your intended use is. Short stuff, say no more then 6 inches long or so, You could likely do good (I can't speak for the cross slide, or compound, they may also be an issue). The longer, and the thinner the project, the wear in the ways will matter more.

From my experience, if the ways are worn that much, the underside of the saddle will also be worn about the same. The cross slide, and compound will also have a good amount of wear. What hurts more then the wear, is the taper formed from the wear being more ate one end, then the other. For the cross slide, and compound, that will be loose at one end, and tight at the other, and no amount of adjustment on the gibbs will take that out.

The compound, is short enough that you can get it close with a long file, but you could quickly mess it up if you are not careful.

The lead screw looks decent, so the half nuts may also be usable.

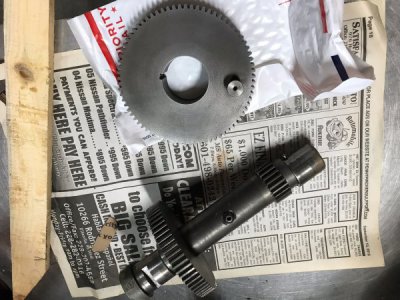

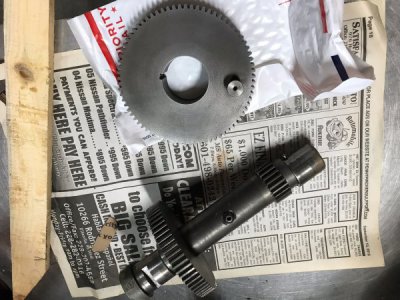

If that new bull gear, and back gear in the pic is included, that helps the price some, But I also agree, the price seems high. But prices, and availability vary a lot by area.