- Joined

- Dec 16, 2014

- Messages

- 85

Suprman - Its stock as far as I know. The prior owner(s) definitely did some funny things to this lathe like tapping holes in odd places in the headstock and removing the countershaft (which I was able to find and install a replacement). So, I wouldn't be surprised if its not the original, but it wasn't anything I modified. I have seen some other cross slide castings that are longer. But, long run I don't think it will matter, as I plan to replace that casting with the MLA T-Slot cross slide eventually. Honestly I never even considered that someone would have modified that part.. But what you say makes sense now that I think about it. It is annoying how much swarf gets in there.

Some of the other projects I have planned or am in progress on:

1. Finish the cleanup and paint of a lever 3c collet closer (Christmas gift)

2. Restore and paint my steady rest (other Christmas gift)

3. MLA T-Slot Cross Slide

4. Scrape flat compound and cross slide faces (intro scraping projects)

5. Make new Large Dial Direct read cross slide dial to replace crappy non stock one on there now.

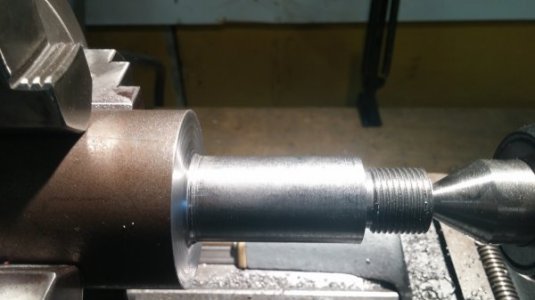

6. Add replacement Acme screw for the cross feed, and install new cross feed nut. The current screw and nut are fairly worn. I have the acme section, but screwed up the dial retention screw threads..

I'll try to update this post with new additions as they are completed or something interesting enough to post happens.

Some of the other projects I have planned or am in progress on:

1. Finish the cleanup and paint of a lever 3c collet closer (Christmas gift)

2. Restore and paint my steady rest (other Christmas gift)

3. MLA T-Slot Cross Slide

4. Scrape flat compound and cross slide faces (intro scraping projects)

5. Make new Large Dial Direct read cross slide dial to replace crappy non stock one on there now.

6. Add replacement Acme screw for the cross feed, and install new cross feed nut. The current screw and nut are fairly worn. I have the acme section, but screwed up the dial retention screw threads..

I'll try to update this post with new additions as they are completed or something interesting enough to post happens.