- Joined

- Dec 7, 2015

- Messages

- 519

A buddy of mine asked me if I could make three of these small little plastic parts out of metal. Seemed easy enough. Yeah- it's small, but so what?

God... I'm such a newb. Projects like this are a frustrating reminder of just how much I have yet to learn. And also a serious kick in the backside to get my new lathe operational. The more I use the old worn out SB, the more frustrated I get. That said, here's another 'getter done.' (Sorry- I don't have a clue what StarWars model he's working on.)

"Hey can you make me three of these plastic parts?"

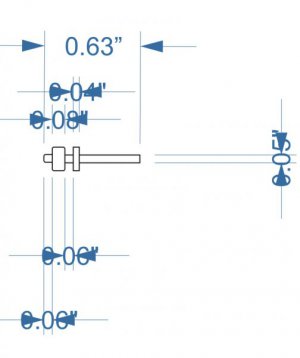

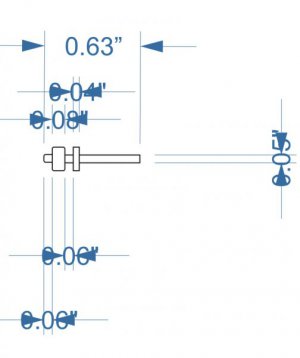

Yeah, probably- send me some dimensions.

"Here you go."

...Hmmmm... Twelve attempts later I finally got three parts complete without breaking off the long stem. That was WAY harder than I think it should have been.

God... I'm such a newb. Projects like this are a frustrating reminder of just how much I have yet to learn. And also a serious kick in the backside to get my new lathe operational. The more I use the old worn out SB, the more frustrated I get. That said, here's another 'getter done.' (Sorry- I don't have a clue what StarWars model he's working on.)

"Hey can you make me three of these plastic parts?"

Yeah, probably- send me some dimensions.

"Here you go."

...Hmmmm... Twelve attempts later I finally got three parts complete without breaking off the long stem. That was WAY harder than I think it should have been.