- Joined

- Nov 23, 2014

- Messages

- 2,612

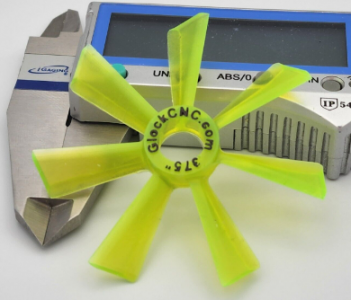

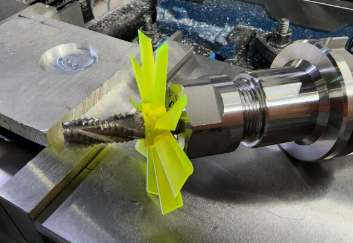

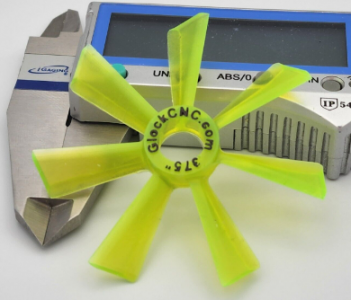

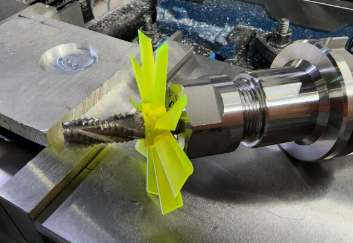

I do an obligatory search on eBay looking at 'Tormach' stuff, this one recently popped up. Anyone here tried them? And, "NO", they aren't fidget spinners for machinists or wheel spinners for end mills! Seems like a plausible concept, though I'm good with the flood coolant on my Tormach. They cost around $6-$9 each depending on size.

Bruce

eBay link to an example:

Bruce

eBay link to an example:

End Mill Chip Clearing Blower Fans - 4 Fans 1/4" Size | eBay

Find many great new & used options and get the best deals for End Mill Chip Clearing Blower Fans - 4 Fans 1/4" Size at the best online prices at eBay! Free shipping for many products!

www.ebay.com