- Joined

- Apr 30, 2015

- Messages

- 11,309

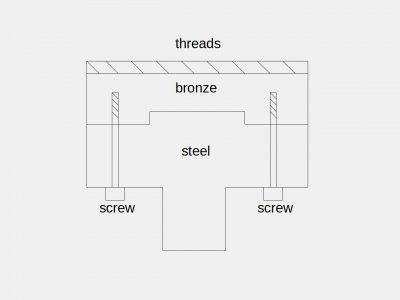

It's more economical to make a composite piece with a threaded brass/bronze section and steel for the body portion- your choice

of methods to attach the two together: screws, brazing, epoxy

Make it so the two pieces fit/lock together for strength in the long direction- I'll do a sketch to show what I mean

something like this:

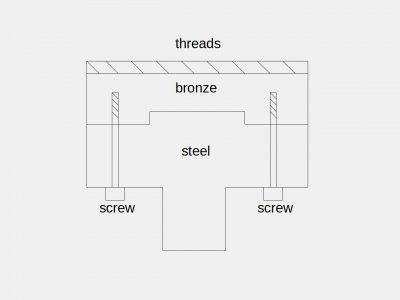

of methods to attach the two together: screws, brazing, epoxy

Make it so the two pieces fit/lock together for strength in the long direction- I'll do a sketch to show what I mean

something like this:

Last edited: