Have had this lathe a bit over a year and maybe 40 hours total of actual use. Most of which has been fixing and tweaking the lath.

Taper was awful when I got the machine and has improved with some cleaning , tightening , measuring and help from members here.

Today I was bored and braved the cold 22’F temp of the “shop”

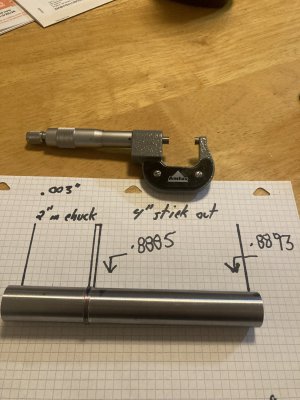

Found a piece if scrap 6” long 15/16 or so in dia , un known steel.

4” stick out did a few light cleaning passes. Then a .002” light cut

Max speed of my lathe is 1600 rpm

Gear set up for .003” on L and .006” on H

Carbide insert tool with new tip

Finish was improvement over some

past attempts .

past attempts .

With my measuring abilities I came up with .0008” taper over 4”

Much better than past attempts and rook a bit of work to improve.

Not sure if I should chase this any more.

Next is better tail stock alignment.

I thought I had it aligned pretty well but turned a 12” long piece and had .010” which I thought was to much and I already made the part it was supposed to fit in. Vs fitting that part to the shaft. It was not critical by any means but sucked one end fit great and the other not so much.

Taper was awful when I got the machine and has improved with some cleaning , tightening , measuring and help from members here.

Today I was bored and braved the cold 22’F temp of the “shop”

Found a piece if scrap 6” long 15/16 or so in dia , un known steel.

4” stick out did a few light cleaning passes. Then a .002” light cut

Max speed of my lathe is 1600 rpm

Gear set up for .003” on L and .006” on H

Carbide insert tool with new tip

Finish was improvement over some

past attempts .

past attempts .With my measuring abilities I came up with .0008” taper over 4”

Much better than past attempts and rook a bit of work to improve.

Not sure if I should chase this any more.

Next is better tail stock alignment.

I thought I had it aligned pretty well but turned a 12” long piece and had .010” which I thought was to much and I already made the part it was supposed to fit in. Vs fitting that part to the shaft. It was not critical by any means but sucked one end fit great and the other not so much.

Last edited: