- Joined

- Dec 18, 2019

- Messages

- 6,527

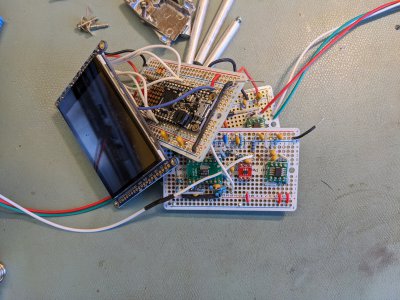

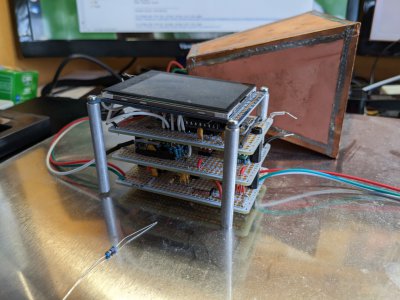

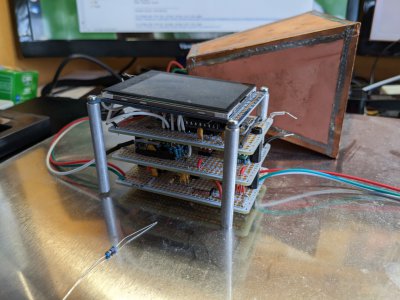

About 3 years ago I built a doppler chronometer out of an eBay X-band doppler module, a home brewed analog front end, an ARM M4 Arduino and a touch panel display. Got it to work ok for my use. Used the knowledge gotten from programming the display, in my ELS project. The chronometer will detect pellets being fired up to 1200 FPS, if I recall correctly. Anyways, it has always been a pile of stacked PCBs and stuff, and never had a proper enclosure. Thought I could rectify that by designing a printed enclosure for it.

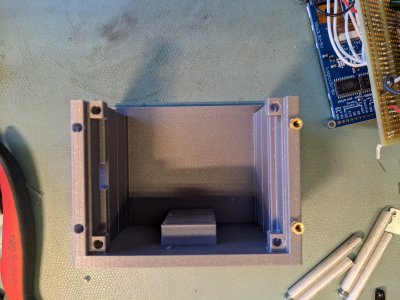

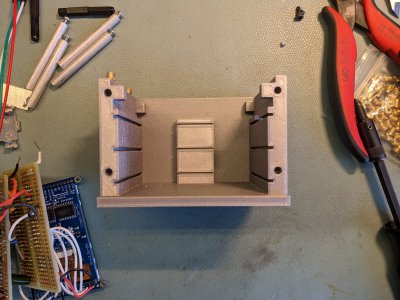

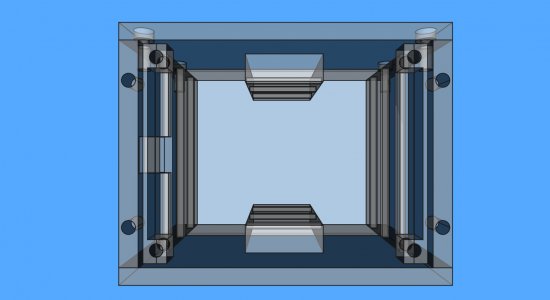

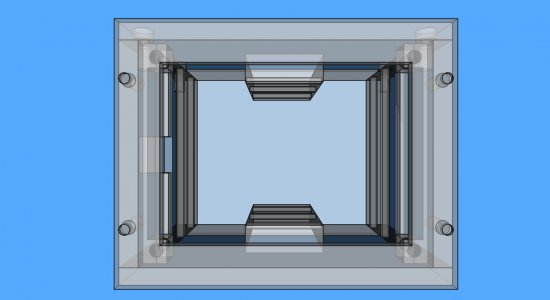

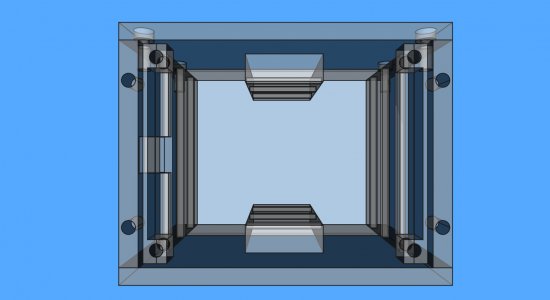

These boards have terrible mounting on them, there's only 2 holes in the prototyping cards. So I designed a sort of card rack where the cards would slide into their respective slots. Looks kind of like this:

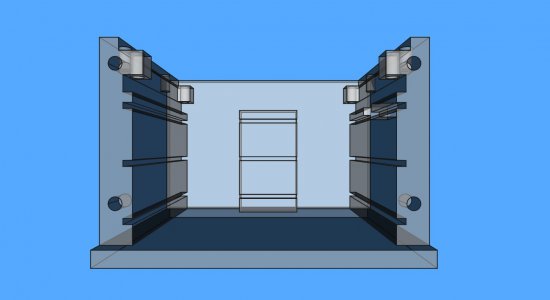

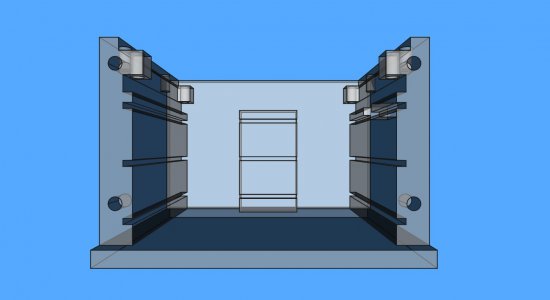

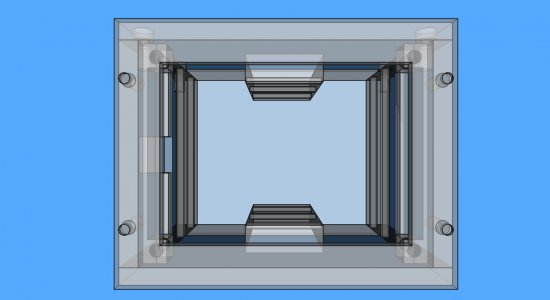

Up near the top, you can see four tab like pieces sticking out that will hold the display. I designed the tabs to accept thermal inserts. The unit is closed up by a cover on the front and the top. I think my best hope of printing this is the back piece sits on the sheet. That way I only will need supports for the tabs and nothing else. The display cover and front cover will be printed separately. Here is the view looking into where the stack of PCBs would be and the display on top.

The parts that are sticking out top and bottom retain the PCBs from rattling around. Finally, I added a cover that allows the display to viewed.

I sliced the first photo using 0.20mm SPEED with supports everywhere at 15% infill and the print time comes out to be 6h 7m. Overall dimensions are 95 x 75 x 65 mm. Is there some way to reduce the print time? Or is this just what happens with something of this complexity and size?

Yes, I scraped off the coating on the antenna elements. Got a few more dB sensitivity.

These boards have terrible mounting on them, there's only 2 holes in the prototyping cards. So I designed a sort of card rack where the cards would slide into their respective slots. Looks kind of like this:

Up near the top, you can see four tab like pieces sticking out that will hold the display. I designed the tabs to accept thermal inserts. The unit is closed up by a cover on the front and the top. I think my best hope of printing this is the back piece sits on the sheet. That way I only will need supports for the tabs and nothing else. The display cover and front cover will be printed separately. Here is the view looking into where the stack of PCBs would be and the display on top.

The parts that are sticking out top and bottom retain the PCBs from rattling around. Finally, I added a cover that allows the display to viewed.

I sliced the first photo using 0.20mm SPEED with supports everywhere at 15% infill and the print time comes out to be 6h 7m. Overall dimensions are 95 x 75 x 65 mm. Is there some way to reduce the print time? Or is this just what happens with something of this complexity and size?

Yes, I scraped off the coating on the antenna elements. Got a few more dB sensitivity.

The PLA is even biodegradable.

The PLA is even biodegradable.