- Joined

- May 15, 2016

- Messages

- 98

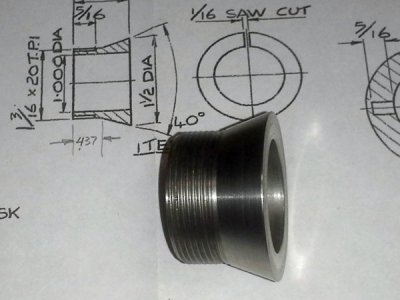

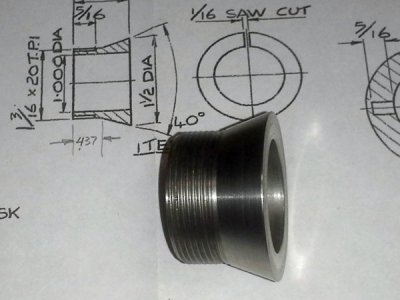

I am making a collet to fit a Quorn Tool and Cutter grinder work head. The collet is 1-1/2" O.D. at the large end and 1.000" I.D. x .812" long. It is to have one slot cut its full length. Material is 303 stainless steel. The collet fit the 1.000" diameter work head arbor before slitting but closed up about .004" after slitting. I am pondering ways to open the collet back up to nominal dimension so it slides easily onto the arbor. I have thought about heating it to relax the fit, adding additional slots not quite full depth to make the collet more flexible, etc.

Any ideas that I may not be seeing?

I have attached a photo for clarity.

Dick

Any ideas that I may not be seeing?

I have attached a photo for clarity.

Dick