-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Single Point Threading Upside Down

- Thread starter calstar

- Start date

- Joined

- Dec 27, 2014

- Messages

- 4,056

Three wires. Embed the three wires in a small chunk of Styrofoam. The wires wont' end up in the chip tray that way.

Good suggestion,

Also make sure your chuck won't unscrew in reverse operation.

Good suggestion,

Also make sure your chuck won't unscrew in reverse operation.

- Joined

- Mar 19, 2014

- Messages

- 2,681

ONE VERY BIG PROBLEM with that idea of cutting threads from the left to right. If you do not engage the half nut all the way in and or miss your mark a tad. The carriage will take off and cut in the wrong place and you will have NO TIME to stop the damage!!! Don’t ask me how I know that! VERY, VERY bad idea unless you come up on it and not just start the cut in a clearance groove like in the video…Dave.

PS: and another tip made on that video was to turn form cutters upside down? The carriage is not made/designed to take a load in that direction. It’s made to take loads in a downward direction. Small and light cuts, I don’t see a problem. But with form cutting, you could have a lot of tool pressure. And you could be putting the wrong forces on your lathe and asking for chatter.

PS: and another tip made on that video was to turn form cutters upside down? The carriage is not made/designed to take a load in that direction. It’s made to take loads in a downward direction. Small and light cuts, I don’t see a problem. But with form cutting, you could have a lot of tool pressure. And you could be putting the wrong forces on your lathe and asking for chatter.

Last edited:

- Joined

- Mar 23, 2014

- Messages

- 31

http://www.eccentricengineering.com.au/index.php?option=com_content&view=article&id=2&Itemid=17

Here is a link for threading from the bottom, or, upside down threading.

Here is a link for threading from the bottom, or, upside down threading.

- Joined

- Oct 31, 2016

- Messages

- 130

Yes I agree CH...ONE VERY BIG PROBLEM with that idea of cutting threads from the left to right. If you do not engage the half nut all the way in and or miss your mark a tad. The carriage will take off and cut in the wrong place and you will have NO TIME to stop the damage!!! Don’t ask me how I know that! VERY, VERY bad idea unless you come up on it and not just start the cut in a clearance groove like in the video…Dave.

PS: and another tip made on that video was to turn form cutters upside down? The carriage is not made/designed to take a load in that direction. It’s made to take loads in a downward direction. Small and light cuts, I don’t see a problem. But with form cutting, you could have a lot of tool pressure. And you could be putting the wrong forces on your lathe and asking for chatter.

While noticing it looks like his lathe has a D1 spindle mount and a collet set up, while cutting brass...

...and saying I have done this off and on on the job in some certain situations on certain lathes for over 30 years:

During early in my apprenticeship back in the day, I was shown this and other"upside down" and reverse set ups on both sides of Y centerline and combinations to think about and try for right and left handed threads...

...while maybe relieving some anxiety of "normal" chasing a fast OD or ID thread towards the chuck, into a relief groove, or into a blind hole on a manual lathe (and I must admit and true, I have had to turn the relief groove a little wider because I over shot it and I crunched a boring bar or 2 in my day (lol),... but yes the anxiety is equaled if you engage a partial ("miss the number") chasing away from the chuck (lol)...and the part (threads) is scrap ifn' you do and don't pull the cutter away just as fast...

...oops; But think about this in the demo; An upside down tool, cutting in reverse spindle direction on that side, the pressure is actually right (is down)

...but as said above; Turning anything in reverse (clockwise) with screw ons without some type of a screw lock or? can turn into a problem and/or dangerous (I love a camlock spindle mount (D1) too but beggars can't be choosers lol)...

I'm sure some peeps around here have added some type of "lock" (set screw?) if it didn't have one to their "garage" lathes screw on chucks and spindle?...

(Possibly just good size set screws through and pushing into/or a slug into a pocket? (pocket ground into the hard spindle? (and threads?)

...just wondering here as I never did but I sometimes thought about it on an old Logan and it's chucks

...there were certain times that I would have liked to turn in reverse even though the chucks screwed on and seated positive and tight, but I didn't

..so anyway, I would and have "done done it" and say OK but a sharp tool of course, small cuts, and depending on the lathe (beef of carriage with crosslide and compound) and a chuck that won't spin off!

Last edited:

- Joined

- Mar 19, 2014

- Messages

- 2,681

...oops; But think about this in the demo; An upside down tool, cutting in reverse spindle direction on that side, the pressure is actually right (is down)

No sorry, the cutting force is trying to pull the carriage UP off the ways/bed.

- Joined

- Oct 31, 2016

- Messages

- 130

...CH; Oops I had it right and then I got all caddywumpassed (thinking about the pressure on the part (spindle) is down his way (tool upside down/clockwise spindle) so I then changed my post with that "oops" (It must be the 4 concussions, 3 skull fractures and 2 subdural hematomas)...But I'm all better now?

....Yes you're right (and I was at 1st before I edited (LOL)...

....The part is cutting and trying to lift the carriage up (So yes, maybe small cuts and/or a somewhat brute machine with a heavy carriage (and crossslide and compound...and tool holder)

...But I agree again wit you (It's "against" the engineering and design)

....Yes you're right (and I was at 1st before I edited (LOL)...

....The part is cutting and trying to lift the carriage up (So yes, maybe small cuts and/or a somewhat brute machine with a heavy carriage (and crossslide and compound...and tool holder)

...But I agree again wit you (It's "against" the engineering and design)

Last edited:

ONE VERY BIG PROBLEM with that idea of cutting threads from the left to right. If you do not engage the half nut all the way in and or miss your mark a tad. The carriage will take off and cut in the wrong place and you will have NO TIME to stop the damage!!! Don’t ask me how I know that! VERY, VERY bad idea unless you come up on it and not just start the cut in a clearance groove like in the video…Dave.

PS: and another tip made on that video was to turn form cutters upside down? The carriage is not made/designed to take a load in that direction. It’s made to take loads in a downward direction. Small and light cuts, I don’t see a problem. But with form cutting, you could have a lot of tool pressure. And you could be putting the wrong forces on your lathe and asking for chatter.

I agree that the carriage is designed for the bearing surface to be taking the load with a anticlockwise turning chuck. if the cutting is done with the chuck rotating clockwise the the cutting force is lifting the cross slide off the lathe bed. on a locked carriage that is fine but if we are trying to traverse the carriage while cutting the carriage will not be sliding on the machines surfaces it was designed to bear on. depending on the lathe some considerable inaccuracies may result.

I do not believe the link to eccentrics web site is for reversed or upside down threading, rather it shows conventional thread cutting, the chuck is rotating normally and so is the advancing cut.http://www.eccentricengineering.com.au/index.php?option=com_content&view=article&id=2&Itemid=17

Here is a link for threading from the bottom, or, upside down threading.

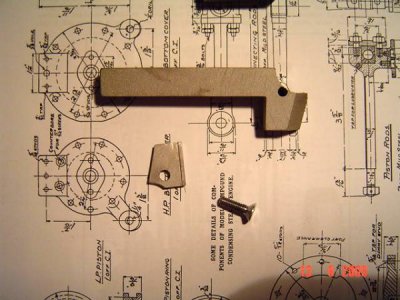

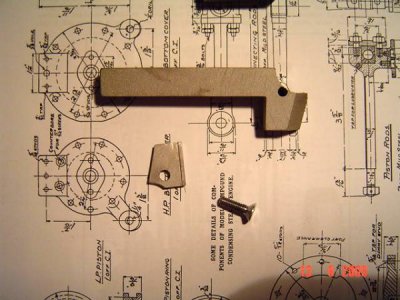

the tool used is the diamond tool holder that holds the cutting bit vertically instead of horizontally as is "normal".

it is however worth considering.