Good morning folks,

I have a Grizzly knee mill that has a 2 HP single phase motor.

The mill uses step pulles and i would like to control the speeds with a VFD.

Is this a possibility? Can i gain anything by doing this?

The motor is currently running on a 20 AMP 220V circuit.

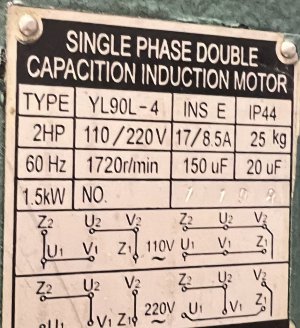

Here is the label on the motor. It has start and run capacitors.

Thanks, Joe

I have a Grizzly knee mill that has a 2 HP single phase motor.

The mill uses step pulles and i would like to control the speeds with a VFD.

Is this a possibility? Can i gain anything by doing this?

The motor is currently running on a 20 AMP 220V circuit.

Here is the label on the motor. It has start and run capacitors.

Thanks, Joe