- Joined

- Sep 22, 2018

- Messages

- 23

Well it finally happened to me. The plastic gear that meshes with the motor stripped. I hardly use this machine, has low hours on it, and yet ......

I looked at replacing the gear from Grizzly as I didn't want to get into rebuild project right now. As many have said, it's a $11 gear and about the same for shipping

I started looking at timing belts and gears on the Automation Direct website and found that found less than $40 shipped I could get a belt and two pulleys. I didn't want to replace the intermediate shaft assembly and thought I'd take my chances on those plastic gears for now. The Automation Direct web page has a calculator to help pick gears and belts based on a known axle spacing. I picked a couple gears that gave me slightly higher spindle speed but not a lot more as I didn't want to lose the low end torque. Playing around with ratios I found a gear combination that would give me nearly exactly 7" long belt path (XL belts coming in one inch increments). They arrived in a matter of days.

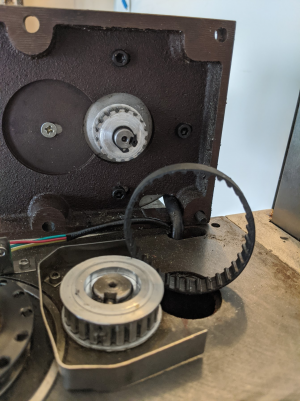

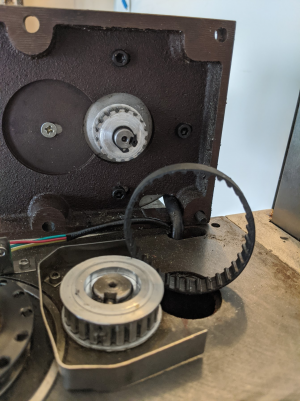

I used my lathe to bore the pulleys to fit and put a recess to accept the snap rings. As can be seen in the last photo, the bottom flange of the drive pulley was taken off (ok, it came off while I was turning the recess ). Two different sized keys would mean a fair amount of expense to get proper broach tooling so I used my lathe and a scrap of flat mild steel ground to size. Broaching with the lathe is a slow method but worked fine for what I need on these aluminum pulleys. Everything went together albeit it a bit tricky to get the belt on the pulleys with very limited access.

). Two different sized keys would mean a fair amount of expense to get proper broach tooling so I used my lathe and a scrap of flat mild steel ground to size. Broaching with the lathe is a slow method but worked fine for what I need on these aluminum pulleys. Everything went together albeit it a bit tricky to get the belt on the pulleys with very limited access.

NOTE: I did no other mechanical mods. No additional spacers. Stock mounting for motor.

The final mod was to switch the black / white wires of the motor at the FWD/REV panel switch as the belt connection changes the spindle direction as compared to the OEM gear connection. Appears to work but have no time on it yet. Below are the Automation Direct parts that I used and a pic of the install before closing it up.

thanks to member @zaaephod for the inspiration to go this route.

steve

70XL037NG

SureMotion timing belt, 1/5in XL pitch, 3/8in wide, 35 tooth, 7in pitch length (circumference), neoprene, fiberglass reinforced.

APB17XL037BF-250

SureMotion timing pulley, aluminum, 1/5in XL pitch, 17 tooth, 1.082in pitch diameter, 1/4in bore, hub with flanges. For use with 3/8in wide belt.

APB24XL037AF-250

SureMotion timing pulley, aluminum, 1/5in XL pitch, 24 tooth, 1.528in pitch diameter, 1/4in bore, no hub with flanges. For use with 3/8in wide belt.

I looked at replacing the gear from Grizzly as I didn't want to get into rebuild project right now. As many have said, it's a $11 gear and about the same for shipping

I started looking at timing belts and gears on the Automation Direct website and found that found less than $40 shipped I could get a belt and two pulleys. I didn't want to replace the intermediate shaft assembly and thought I'd take my chances on those plastic gears for now. The Automation Direct web page has a calculator to help pick gears and belts based on a known axle spacing. I picked a couple gears that gave me slightly higher spindle speed but not a lot more as I didn't want to lose the low end torque. Playing around with ratios I found a gear combination that would give me nearly exactly 7" long belt path (XL belts coming in one inch increments). They arrived in a matter of days.

I used my lathe to bore the pulleys to fit and put a recess to accept the snap rings. As can be seen in the last photo, the bottom flange of the drive pulley was taken off (ok, it came off while I was turning the recess

NOTE: I did no other mechanical mods. No additional spacers. Stock mounting for motor.

The final mod was to switch the black / white wires of the motor at the FWD/REV panel switch as the belt connection changes the spindle direction as compared to the OEM gear connection. Appears to work but have no time on it yet. Below are the Automation Direct parts that I used and a pic of the install before closing it up.

thanks to member @zaaephod for the inspiration to go this route.

steve

70XL037NG

SureMotion timing belt, 1/5in XL pitch, 3/8in wide, 35 tooth, 7in pitch length (circumference), neoprene, fiberglass reinforced.

APB17XL037BF-250

SureMotion timing pulley, aluminum, 1/5in XL pitch, 17 tooth, 1.082in pitch diameter, 1/4in bore, hub with flanges. For use with 3/8in wide belt.

APB24XL037AF-250

SureMotion timing pulley, aluminum, 1/5in XL pitch, 24 tooth, 1.528in pitch diameter, 1/4in bore, no hub with flanges. For use with 3/8in wide belt.