Hi

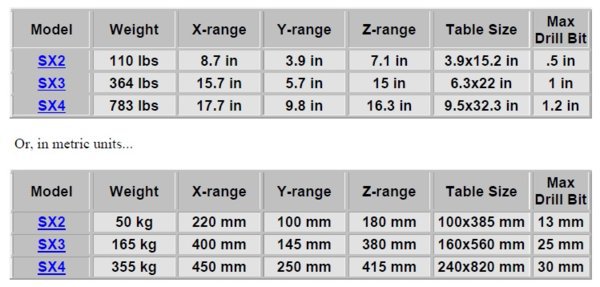

Have ordered a new Sieg SX4 Mill to replace my SX3 - Delivery several months.

In order to get things underway I wish to make a new base/stand somewhat higher than my old machine.

To this end what is the consensus for how high the table should be relative to ones height/ perhaps elbow high ? I am relatively short 5'5" but found my old SX3 is too low so I am constantly bending over.

Also if anyone has a Seig SX4 can you supply the dimensions of the base and the Z travel ( for new DRO Scales)

Thanks Ron

Have ordered a new Sieg SX4 Mill to replace my SX3 - Delivery several months.

In order to get things underway I wish to make a new base/stand somewhat higher than my old machine.

To this end what is the consensus for how high the table should be relative to ones height/ perhaps elbow high ? I am relatively short 5'5" but found my old SX3 is too low so I am constantly bending over.

Also if anyone has a Seig SX4 can you supply the dimensions of the base and the Z travel ( for new DRO Scales)

Thanks Ron