- Joined

- Mar 14, 2024

- Messages

- 5

Hey everyone!

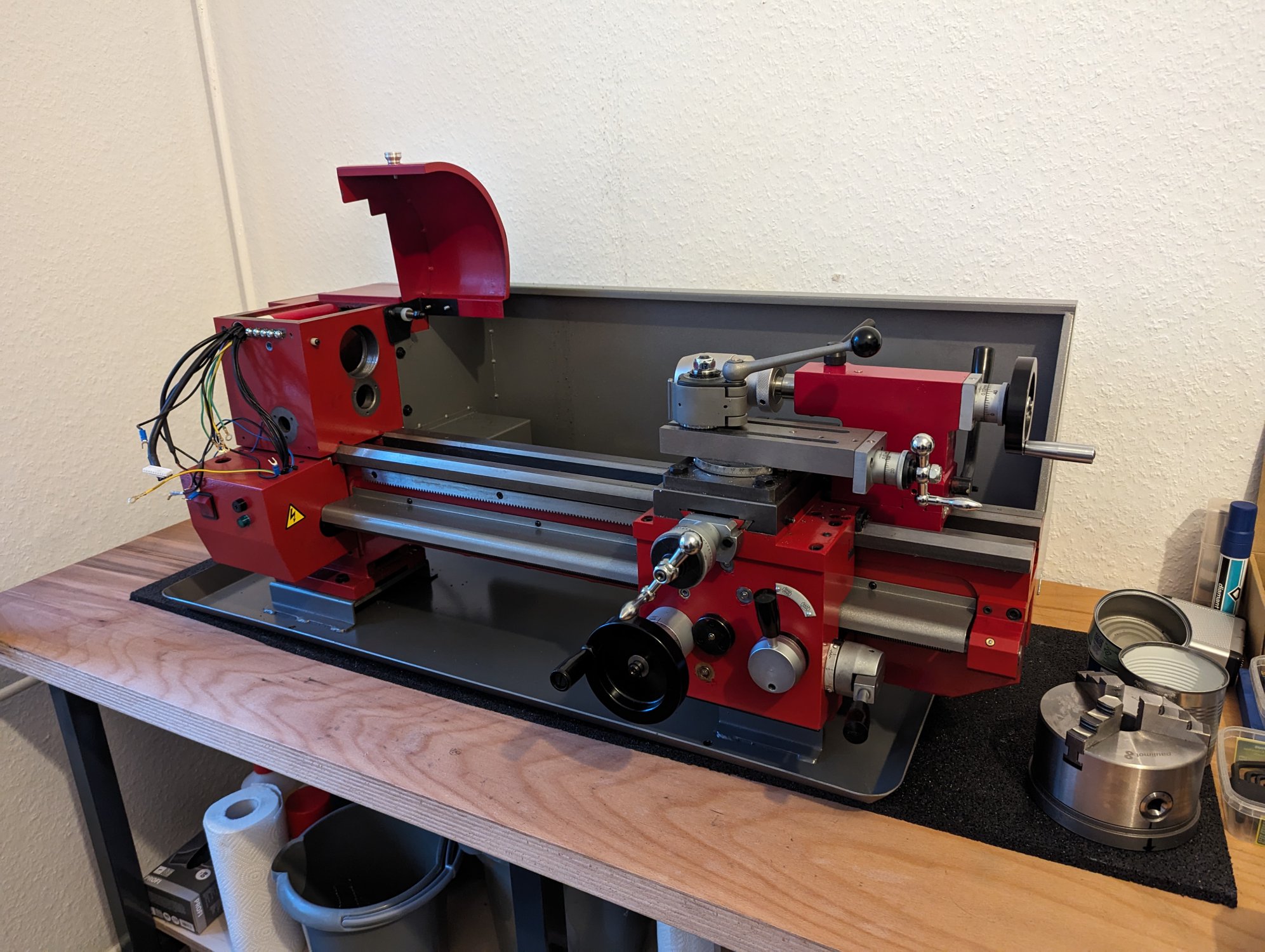

I wanted to share my experience converting my SIEG SC4 Lathe to a full belt drive system. As I keep my lathe in my apartment, the noise generated from the straight-toothed gears in the headstock was problematic. These gears transfer torque from the intermediary shaft to the main spindle shaft and were loud enough to prevent me from using the optimal spindle rpm for my projects.

Here are some noise level measurements I recorded:

Before the conversion (with Leadscrew Gears disengaged)

Considering that an increase of 10 dB roughly doubles the perceived loudness, this reduction has made a significant difference.

In addition to switching to a belt drive, I upgraded all the bearings to higher-quality SKF ones. This improvement also enhanced the lathe's precision, reducing runout from between 0.02-0.03 mm to just 0.01 mm. GreatOldOne’s post is a goldmine of information for anybody wanting to upgrade the headstock bearings.

I hope this information is of interest or helps anyone thinking about making similar upgrades!

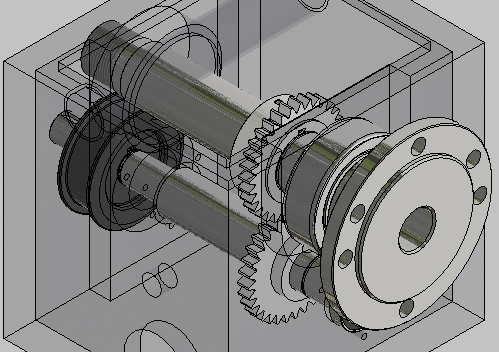

The standard headstock assembly in CAD

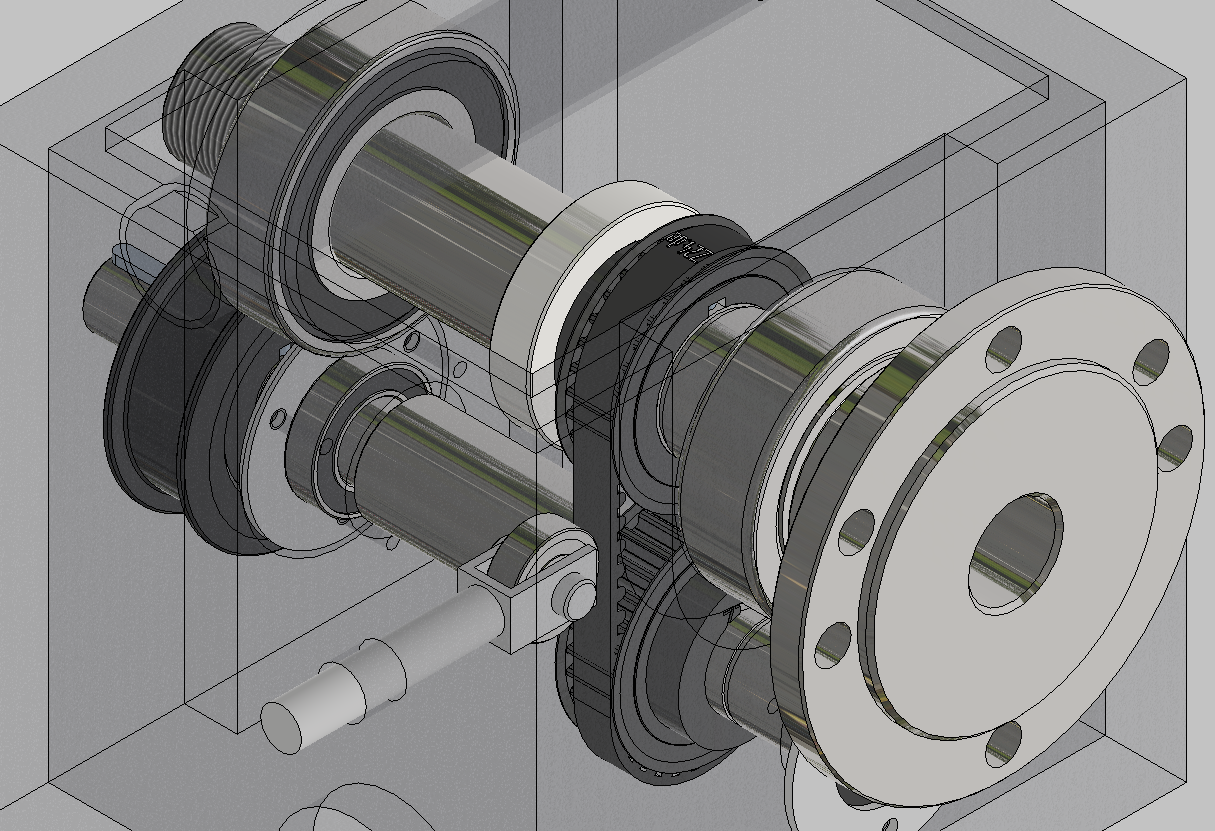

The revised assembly with mock-tensioner, timing pulleys and belt

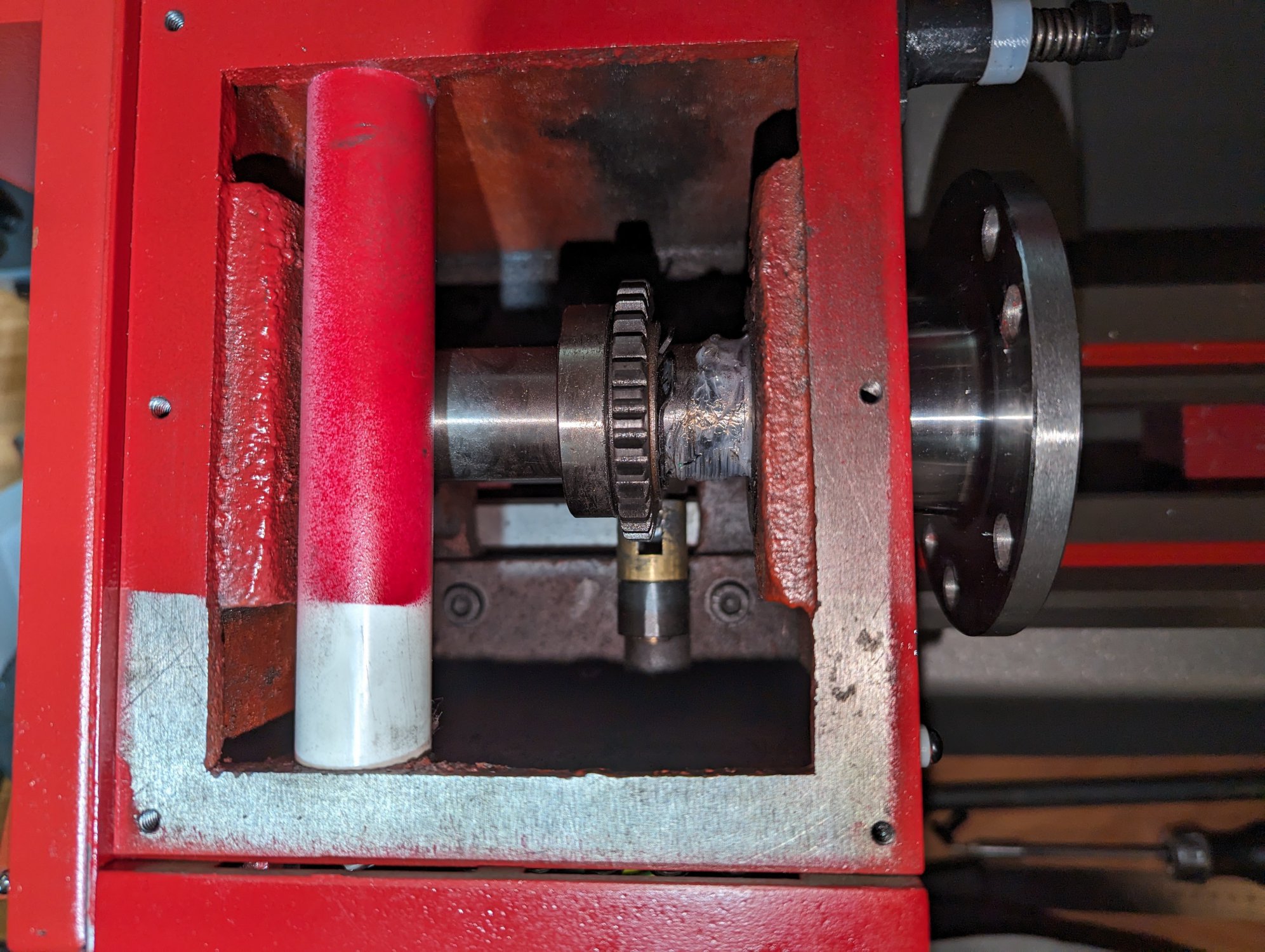

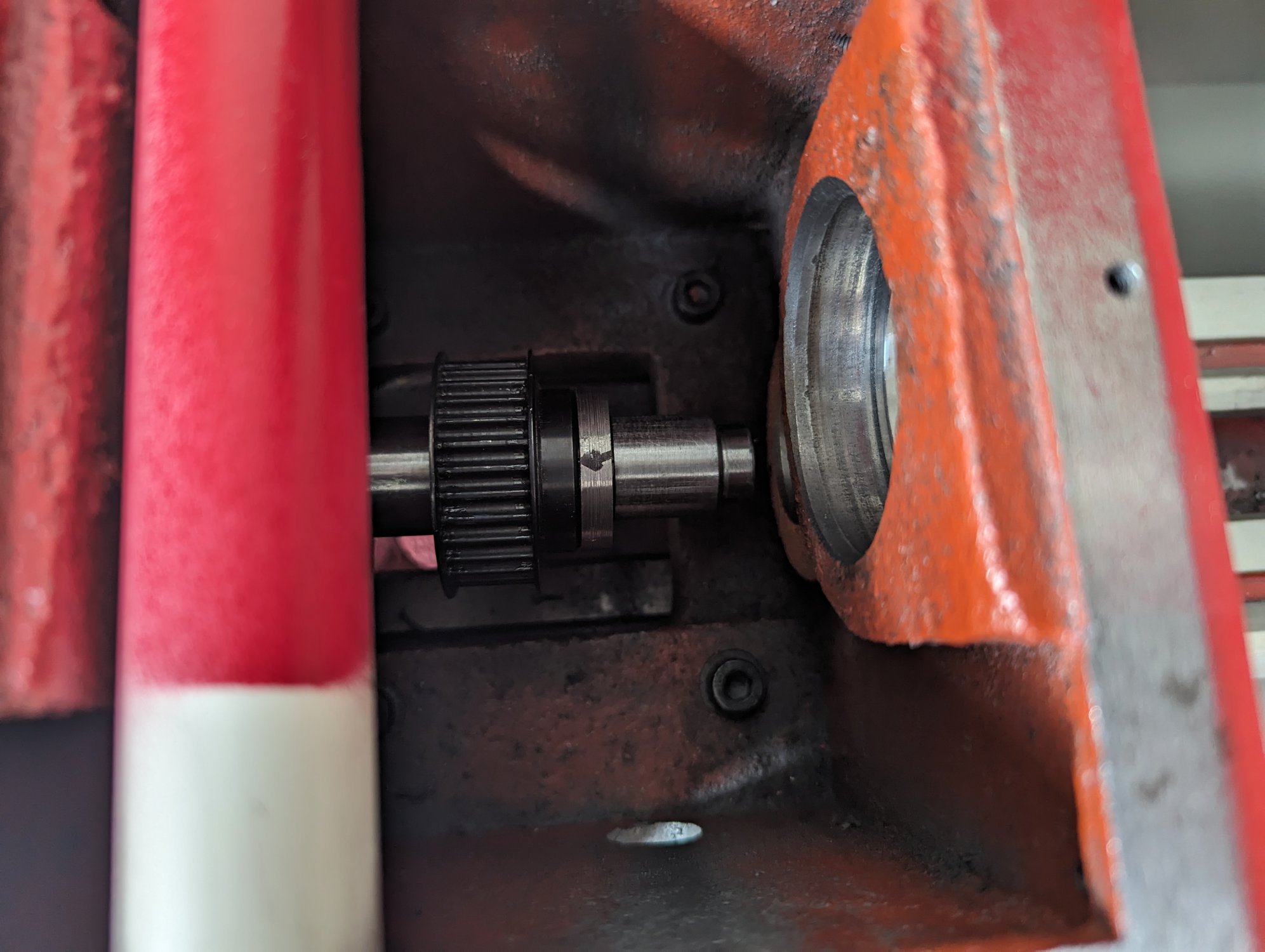

A view inside the headstock… The straight toothed gears had a great deal of backlash and aren’t a great fit on the shafts. The bottom gear can be disengaged via a knob on the control panel. This is because a milling attachment can be used with the lathe and this disengagement stops the main spindle from spinning while carrying out milling operations. As I won’t be using a milling attachment this function isn't necessary.

Full Parts List for the conversion which came to a total of 95,00 EUR:

• 1x Bearing Spindle Shaft (Front) 32007 X SKF 35x62x18

• 1x Bearing Spindle Shaft (Rear) 6206-2RS1 SKF 30x62x16

• 2x Bearing Intermediary Shaft 61903-2RS1 SKF 17x30x7

• 2x HTD ZRS 30-5M-15 Timing Pulleys (both modified on the lathe to fit the two shafts)

• 1x 265-5M-15 mm Timing Belt (same type of belt as the one between motor/intermediary shaft)

• New Circlips for both shafts

• Bearing Grease

Before disassembling the headstock assembly, I made some modifications to the pulleys. The turning of the final inside diameter was done on another lathe to ensure a good fit as it could be tested with the shafts.

Out with the old…

…and in with the new!

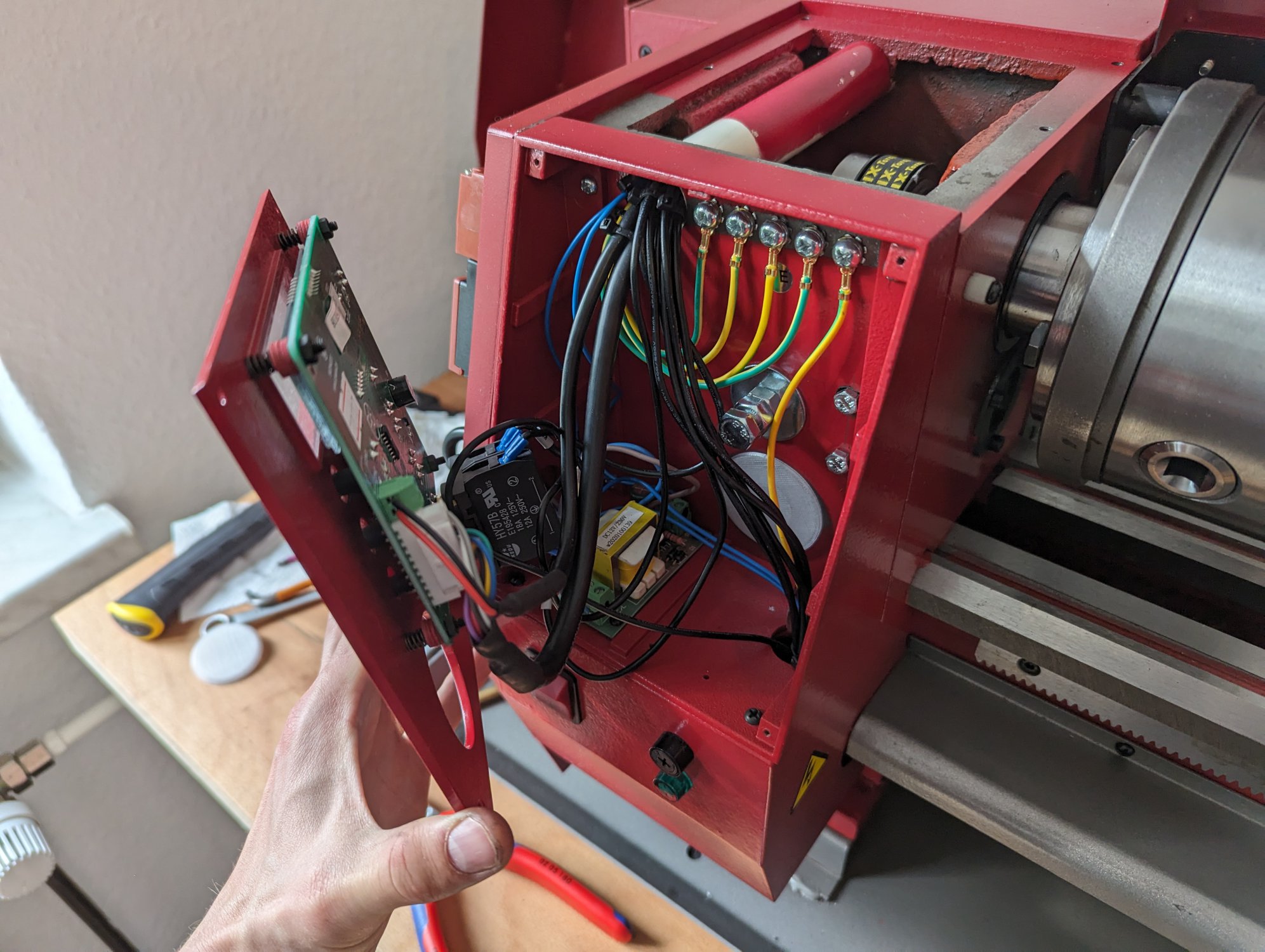

The knob to disengage the gears was removed and the tensioner assembly fitted.

All back together and running much quitter than before! Slight annoyance is to have to run the lathe in "reverse” as now the intermediary and main spindle shaft turn in the same direction rather than opposing as with the toothed gear connection. As a result of this there is also no need for the 2nd 42-tooth-gear for the leadscrew gearbox, as Gear A can be placed directly onto the intermediary spindle shaft instead of the spacer. This insures the power feed runs in the correct direction (towards the headstock) when the lathe is running in "reverse". Didn't worry to much about this as an Electronic Leadscrew Conversion could be next...

A noise comparison video at 1000 rpm:

I wanted to share my experience converting my SIEG SC4 Lathe to a full belt drive system. As I keep my lathe in my apartment, the noise generated from the straight-toothed gears in the headstock was problematic. These gears transfer torque from the intermediary shaft to the main spindle shaft and were loud enough to prevent me from using the optimal spindle rpm for my projects.

Here are some noise level measurements I recorded:

Before the conversion (with Leadscrew Gears disengaged)

- 80 dB at 500 rpm

- 87 dB at 1000 rpm

- 68 dB at 500 rpm

- 73 dB at 1000 rpm

- 77 dB at 1500 rpm

- 80 dB at the maximum speed of 2000 rpm

Considering that an increase of 10 dB roughly doubles the perceived loudness, this reduction has made a significant difference.

In addition to switching to a belt drive, I upgraded all the bearings to higher-quality SKF ones. This improvement also enhanced the lathe's precision, reducing runout from between 0.02-0.03 mm to just 0.01 mm. GreatOldOne’s post is a goldmine of information for anybody wanting to upgrade the headstock bearings.

I hope this information is of interest or helps anyone thinking about making similar upgrades!

The standard headstock assembly in CAD

The revised assembly with mock-tensioner, timing pulleys and belt

A view inside the headstock… The straight toothed gears had a great deal of backlash and aren’t a great fit on the shafts. The bottom gear can be disengaged via a knob on the control panel. This is because a milling attachment can be used with the lathe and this disengagement stops the main spindle from spinning while carrying out milling operations. As I won’t be using a milling attachment this function isn't necessary.

Full Parts List for the conversion which came to a total of 95,00 EUR:

• 1x Bearing Spindle Shaft (Front) 32007 X SKF 35x62x18

• 1x Bearing Spindle Shaft (Rear) 6206-2RS1 SKF 30x62x16

• 2x Bearing Intermediary Shaft 61903-2RS1 SKF 17x30x7

• 2x HTD ZRS 30-5M-15 Timing Pulleys (both modified on the lathe to fit the two shafts)

• 1x 265-5M-15 mm Timing Belt (same type of belt as the one between motor/intermediary shaft)

• New Circlips for both shafts

• Bearing Grease

Before disassembling the headstock assembly, I made some modifications to the pulleys. The turning of the final inside diameter was done on another lathe to ensure a good fit as it could be tested with the shafts.

Out with the old…

…and in with the new!

The knob to disengage the gears was removed and the tensioner assembly fitted.

All back together and running much quitter than before! Slight annoyance is to have to run the lathe in "reverse” as now the intermediary and main spindle shaft turn in the same direction rather than opposing as with the toothed gear connection. As a result of this there is also no need for the 2nd 42-tooth-gear for the leadscrew gearbox, as Gear A can be placed directly onto the intermediary spindle shaft instead of the spacer. This insures the power feed runs in the correct direction (towards the headstock) when the lathe is running in "reverse". Didn't worry to much about this as an Electronic Leadscrew Conversion could be next...

A noise comparison video at 1000 rpm: