So I got this M1099 lathe second hand for a great deal a couple years ago and for the most part I like it. It's not the slickest machine around to use but I can do basically everything I want to do with a lathe of this size. It's a version of the Grizzly G0602 and a couple of other Grizzly lathes in this size that all have slight variations. I was pleased to find that this lathe actually has an 11" swing over the ways, not 9 or 10" like they say in some of their different advertisements and manuals.

I ran into a problem recently though. I made a fly cutter plate in the mill and made the arbor in the lathe. Because you can't make threads on a mill, I tapped the hole 3/4-16 using a standard tap out of a set because I was using a 1" piece of stock to make the arbor, and I had the right tap as well. On the lathe I single-point threaded the arbor to screw into that hole. Well, I made the thread and checked it on my part, and it wouldn't fit. I went back and checked the chart and the change gears 3 times to make sure I had everything correct. I tried a 3/4-16 bolt in my part, and it fit. I tried a 3/4-16 nut on the arbor, and it would not fit. I re-measured the dimensions, and I found that the threads were even slightly undersized because I overshot my threads (I'm still learning). Still didn't fit. I pull out a thread gauge and lo and behold, it will not fit the threads on the arbor.

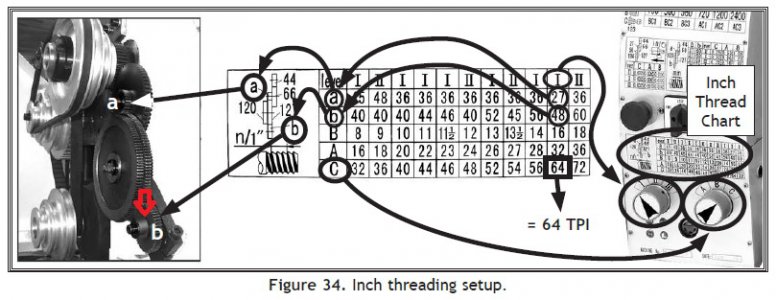

I thought about this a bit and grabbed up a metric thread gauge and it was dead on a 1.50 metric thread pitch. I go back over to the threading charts and compare the 1.50 and 16tpi thread change gears and dial settings. Turns out they're identical. When I bought this lathe I thought I was getting a metric/inch lathe, but what I got instead was a metric lathe with a second threading chart that gives close approximations to the tpi threads using the metric threading gears. What's interesting is that I can't find any mention about this problem anywhere on the internet about these little Grizzly and Shop Fox lathes, and I did search quite a bit.

That said, I have a long shot question for others who own these. Is there a way to actually cut proper inch threads on this machine, like a custom set of change gears or something that I can buy from someone? Also, before you answer, I did already check and even though the Grizzly lathes have different tooth counts on the change gears, they all have the same threading charts with the inch threads being substituted metric threads. I really do think it's a great little lathe otherwise, but I need the ability to do inch threads. On this particular job, if I had known ahead of time, I would've just tapped the plate 19-1.5 and made the arbor to the metric spec. I even had the tap on hand, but a lot of the stuff I'm working with is American-made old tractors, cars, and other machinery that use inch standard fasteners, and I've even toyed with British cars here and there with their Whitworth fasteners. I don't thread very often obviously, and that's why I was okay with the cumbersome threading gear change setup, but this is disappointing right here because I can't use it for those custom-made fasteners that are unobtainium (or insanely expensive). Anyway, thanks in advance if anyone has any info. I may be looking for a new lathe too if anyone's got suggestions. I'm thinking of going bigger/heavier too if I do.

I ran into a problem recently though. I made a fly cutter plate in the mill and made the arbor in the lathe. Because you can't make threads on a mill, I tapped the hole 3/4-16 using a standard tap out of a set because I was using a 1" piece of stock to make the arbor, and I had the right tap as well. On the lathe I single-point threaded the arbor to screw into that hole. Well, I made the thread and checked it on my part, and it wouldn't fit. I went back and checked the chart and the change gears 3 times to make sure I had everything correct. I tried a 3/4-16 bolt in my part, and it fit. I tried a 3/4-16 nut on the arbor, and it would not fit. I re-measured the dimensions, and I found that the threads were even slightly undersized because I overshot my threads (I'm still learning). Still didn't fit. I pull out a thread gauge and lo and behold, it will not fit the threads on the arbor.

I thought about this a bit and grabbed up a metric thread gauge and it was dead on a 1.50 metric thread pitch. I go back over to the threading charts and compare the 1.50 and 16tpi thread change gears and dial settings. Turns out they're identical. When I bought this lathe I thought I was getting a metric/inch lathe, but what I got instead was a metric lathe with a second threading chart that gives close approximations to the tpi threads using the metric threading gears. What's interesting is that I can't find any mention about this problem anywhere on the internet about these little Grizzly and Shop Fox lathes, and I did search quite a bit.

That said, I have a long shot question for others who own these. Is there a way to actually cut proper inch threads on this machine, like a custom set of change gears or something that I can buy from someone? Also, before you answer, I did already check and even though the Grizzly lathes have different tooth counts on the change gears, they all have the same threading charts with the inch threads being substituted metric threads. I really do think it's a great little lathe otherwise, but I need the ability to do inch threads. On this particular job, if I had known ahead of time, I would've just tapped the plate 19-1.5 and made the arbor to the metric spec. I even had the tap on hand, but a lot of the stuff I'm working with is American-made old tractors, cars, and other machinery that use inch standard fasteners, and I've even toyed with British cars here and there with their Whitworth fasteners. I don't thread very often obviously, and that's why I was okay with the cumbersome threading gear change setup, but this is disappointing right here because I can't use it for those custom-made fasteners that are unobtainium (or insanely expensive). Anyway, thanks in advance if anyone has any info. I may be looking for a new lathe too if anyone's got suggestions. I'm thinking of going bigger/heavier too if I do.