I have the Supermax horizontal which I believe was a licensed copy of the Shizuoka probably from the late 1980’s or early 1990’s. My machine is the horizontal-only version but the inner workings of the lower part of this machine are very similar. I believe the horizontals had a 50 taper and the vertical/horizontal combinations had a 40 taper on the horizontal.

One thing I really like about this machine is its backlash compensating system which works well. The x-axis screw is stationary – does not rotate. The split gear-driven nut in the center provides the drive. One half of the split is rotated by a screw which is accessed by a round knurl knob in front of the saddle. This allows you to twist one half of the nut against the other virtually eliminating backlash. This allows this mill to do climb milling without much excitement even with larger stagger tooth cutters. Something that is not always the case with mills of this size.

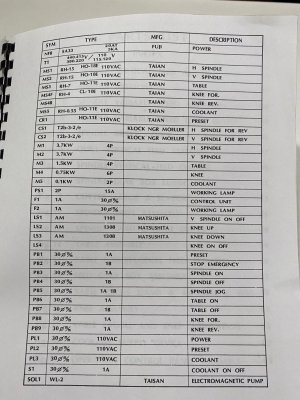

My machine even without the vertical head has four motors – a 5 hp spindle motor, a 2 hp feed motor, a 1 hp rapid motor and 1/4 hp coolant pump.

It is a good heavy well-made mill. I’ve had mine apart when I was cleaning and inspecting the machine.

One side note, when I was changing oil in the feedbox, I went with a slightly heavier version than was specified. This feedbox has a cone clutch for the rapids. This heavier oil would on occasion cause the cone clutch to stick in the engaged position. Not a good situation. Going to the correct oil completely eliminated this.

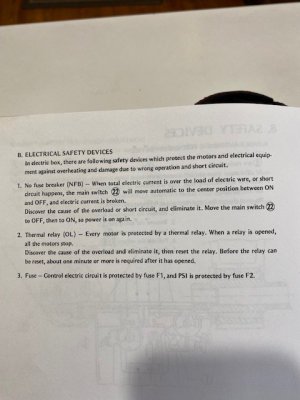

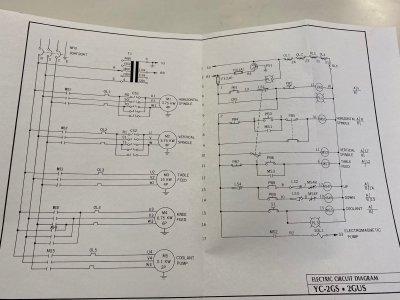

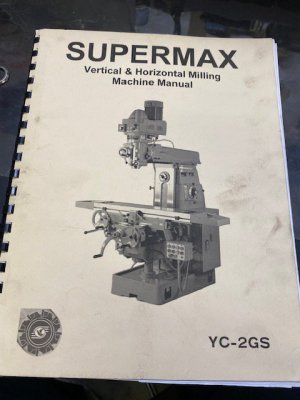

I’ve posted a few pictures of mine plus a manual that I have.

Thanks!

Thanks!

Thanks!

Thanks!