Projectnut, your lathe looks quite similar. Would you please describe to me the operation of the levers on the apron? What is the one that swings in-out?

I did get to see the Sheldon last night. (Not optimal, cold, getting dark no lights, others milling around..).

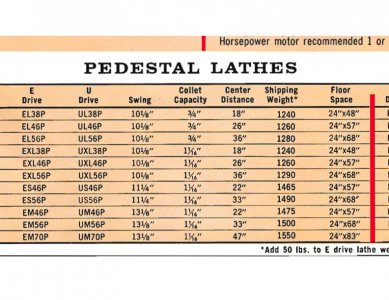

It is a Sheldon EXL-56-P, serial EXL-30352.

By the literature I found, the XL variety is a 10" swing with "short" 5MT spindle taper; D1-4" cam lock spindle; 1.37 dia spindle thru-hole.

It has 8 speeds in open belt, plus 8 in back gear.

I'm not sure on the motor, but the plug-in looked like any regular 220 volt outlet/plug. Hit the switch and it ran, maybe noisier than I expected.

Is this machine really weighing in at 1400 lbs?? And of course, what are these lathes typically priced at?

I've owned two Sheldon lathes and am very happy with the one I still have (same model, just found one with a taper attachment). There is a very active Sheldon owner's group with a lot of manuals and documentation available...and very helpful people who really know the machines. I'll put a link at the end.

In general, Sheldon's lathes were very robust for their swing size and tend to be heavier than many of their competitors. I wouldn't doubt that machine is in the ballpark of 1,400lbs but that may be the cited shipping weight, so a touch less as it sits...maybe 1,200lbs. The one you're looking at has a later, much more desirable D1-4 spindle, which is a huge plus. The only thing I don't see in the picture is a follow rest, which is handy to have. That's the one thing missing from my Sheldon...they show up on eBay from time to time, but more commonly in the smaller sizes, so I'm going to fabricate one. The short 5MT spindle taper can make it hard to find a collet adapter, or dead center, but you can always just get a collet chuck if it doesn't have the collet adapter.

Being a gear head machine they will be quite a bit nosier than something like a South Bend with belt drive. I notice a big difference in back gear and when the power feed gearbox is engaged. I actually just replaced one of the gears in the power feed drive train with a 3D printed gear and it's probably 25% quieter now.

As far as the apron controls go, you have three levers. On the upper right you have the half-nut lever which is only used for thread cutting. It's only used for that to limit wear and because it's not clutched, so if you crash the tool into the chuck it's not stopping. To the left and slightly lower than the half-nut lever is a three-position power feed selector. In the middle position the carriage is free to turn with the hand wheel, or under power by the half-nut. Move the selector to the right position and it sends power feed to the carriage. Move the selector lever to the right and it sends power feed to the cross slide. The lever that moves in/out at the bottom is the clutched lever to actually engage the power feed to either the carriage or cross slide. The good thing with the power feed using a clutch is that if you crash the tool into the chuck it will slip and hopefully limit the amount of damage.

For either the half-nut or power feed to work you have to have a feed rate/TPI selected on the quick-change gearbox, and move the lever that is above and to the left of the QCGB either up or down (with the lathe stopped). That engages gears between the headstock and the QCGB which turns the lead screw. The brass tag on the QCGB has both feed rates in inches per revolution and threads per inch. When you're using the half nut, the TPI is what you look at, and when you're using power feed the IPR is what you look at. If you set the QCGB levers in a certain position and compared what happens using power feed and the half-nut, it moves much faster with the half-nut....drastically so.

I would look at a couple of things if you go back. One, check that the half-nut and power feeds work. Two, pop the cover off the top of the QCGB with a flat-blade screwdriver and look at the gears for missing/broken teeth. Three, open the left side cover and look at all those gears for missing/broken teeth as well. Four, open the headstock cover, turn the chuck by hand and check all the teeth on the bull gear, which is the big gear closest to the chuck. Then disengage the pin that locks the spindle together so the chuck turns without moving the rest of the spindle. At that point, engage the back gear which is at the back left corner of the headstock...pull out on the knob, and rotate the handle towards you. You likely won't be able to turn the chuck by hand, but if you can power it up, check that you don't have much more than a bit of clatter/noise (there will definitely be some). That's not fatal, but requires a simple adjustment to avoid gear tooth damage. Lastly, move the tailstock as far right as you can, then run the carriage the full length from left to right a couple of times. Most wear is near the chuck since that gets used the most, so you're looking for it gliding smoothly near the chuck and then really dragging terribly near the tailstock end....signs of a lot of wear.

If it all checks out, the price should vary a lot....are there any other chucks, is the follow rest there, is there a collet adapter/closer, etc. With just what I can see, and no obvious damage or problems, around here it's probably a $1,500 machine, but in other parts of the country it's probably $2,500 since the supply is much lower.