I have actually been considering doing something similar. Since I don't have access to metal casting facilities and I'm not sold enough on the idea of designing my own shaper from scratch and having it cast by another, I thought I'd see how far I could get with one of these (which I already own):

http://www.harborfreight.com/6-inch-cross-slide-vise-32997.html

View attachment 81819

If you squint, you can just see the makings of a traversing head shaper, much like the ones seen here:

http://www.lathes.co.uk/perfecto/page2.html

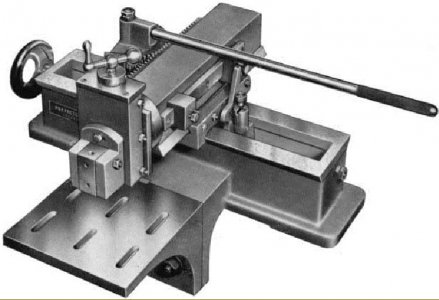

View attachment 81820

I've already torn down my old cross-slide vise (which has seen its share of better days) and am slowly contemplating what it would need to become a handy little shaper. I've got a couple nice chunks of cast iron that I would use to build the clapper, the tool slide, and other bits and bobs.

View attachment 81821

I'd really like to have my little shaper be powered by an electric motor rather than Duncan power, as that would allow me to do other things in the meantime, or just watch it work. I've already got a nice set of 100 tooth and 28 tooth gears from Boston to handle the motor reduction. Now I'm just trying to decide on a style of drive, simple crank and rod or Whitworth quick return. Also, where would I mount the motor? On the machine itself, or off to the side with an idler to take up the slack as the head moves nearer and further. I'm also trying to decide what kind of work table to add and how it will attach to the shaper-née-vise. A pair of angle plates would serve as a mounting plate for the vise-shaper and the other as a table that can be slid up and down to accommodate various sizes of work.