- Joined

- Oct 7, 2020

- Messages

- 2,116

Thanks guys,

There sure is a lot to figure out on getting a part setup correctly on a rotary table. Thanks again for all the help everyone.

With all the help here and a couple of videos I have a much better idea of what needs to happen. I have seen the Joe Pie video in the past and watched it again yesterday. I can see where the bar attached to the table is a great idea, I'll work on that.

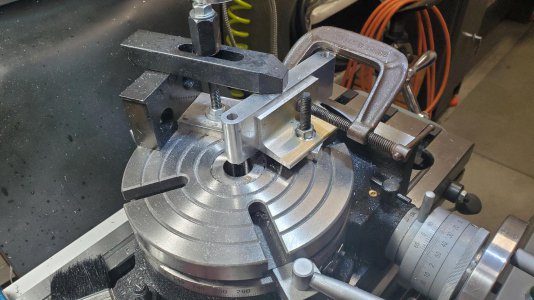

I'll work on it tomorrow and get some photos of what I do.

There sure is a lot to figure out on getting a part setup correctly on a rotary table. Thanks again for all the help everyone.

With all the help here and a couple of videos I have a much better idea of what needs to happen. I have seen the Joe Pie video in the past and watched it again yesterday. I can see where the bar attached to the table is a great idea, I'll work on that.

I'll work on it tomorrow and get some photos of what I do.