Ok, so a friend here is threatening to embarrass me if I don't report on how this new belt drive actually works (probably don't need to mention his name...

So I clamped a piece of HRS I had laying around and took a 50 thou swipe. Not even sure the mill knew it was cutting anything. My apologies everyone, as I've gotten used to using smaller machines over the last decade and am used to the machine being the limiter of my cuts instead of the material and cutter.

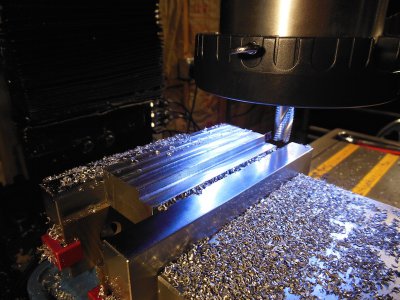

So I took a .25 DOC full-width pass with a 1/2" fine carbide rougher at a fairly moderate pace on the power feed. I think El Hefe knew he was cutting something, but it barely registered. Chips were coming out a little blue so I backed off the spindle speed and the feed rate a bit and the mill just hummed along smooth as butter. No muss, no fuss. And hardly any noise at all. This thing is almost TOO quiet.

I am going to go through a phase here where I am going to toast a few cutters here and there, as I am not used to having a machine that can overpower a cutter in very short order. (prior to the belt change I took a 3/8" carbide rougher and buried it full depth in 1" thick steel like I was profiling a piece of wood on a jigsaw. Dark blue chips, and could have used a bit of coolant to protect the cutter, but the mill wasn't even straining a bit. I'm really liking this mill...)

So anyway, here's a few 'action shots' to appease Charles (oops...) :rofl:

View attachment 93859

View attachment 93860

View attachment 93861

View attachment 93863

Here's a quartering shot of El Hefe wearing his new belt drive. I think he looks pretty good. But then I'm probably biased a bit.

View attachment 93864

I need to come clean on something though: I screwed up the reinstall of the electrical somehow (well...I know what I did, just not sure how). The motor now spins opposite of what it used to. So...I promptly ruined a brand new 1/2" carbide end mill before I realized what had happened. :angry: Lets just say there were plenty of 'bad words' flying around the shop for a bit as I examined three chipped flutes out of four.

But rather than ruin the moment, I just put the fwd/rev switch in reverse and took the cuts and pictures. But after stopping and starting the machine a few times I decided I liked the fact that you turn the switch clockwise to get the motor spinning clockwise and counterclockwise to spin the motor counterclockwise. So I took a sharpie and lined out the words 'Forward' and 'Reverse' on the switch and put a big 'F' and 'R' in the top corners of the switch label. It just makes sense to me this way (OK, I'm left-handed/right-brained but so what...) Those of you who are machine purists can gasp if you want but I'm going to leave it like this. :lmao:

Nobody's perfect. Least of all me.