- Joined

- Sep 1, 2020

- Messages

- 1,591

All of the next paragraph are copy and pasted from facebook and slightly edited for my current progress.

Hello, I have only been taught for a couple of hours how to scrape, the rest is reading and YouTube. I am trying to get better at scraping to scrape in my metal planer.

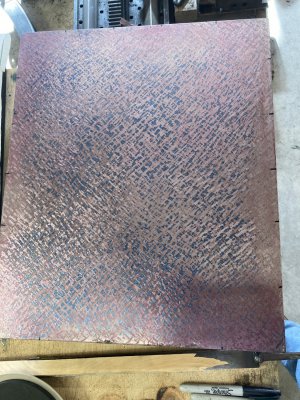

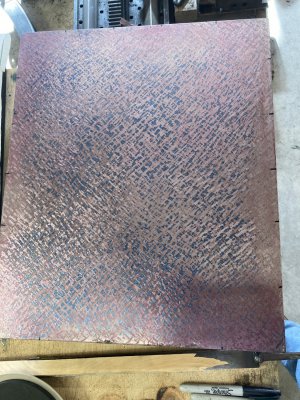

My surface plate is a 10”x12” Chinese A grade that had its own “certificate”. I use dykem high spot blue as the ink and a speed ball roller. I put the ink on a sheet of glass then transfer it to the surface plate. I then wipe down both surface plates with my hand to get rid of any dust. Lift up the inked one, flip it over and lower it on the cast iron plate (15”x18”). I move the granite plate around on the cast iron plate making sure to not got over an inch off the edges. I already checked for dishing and doming with feeler gauges and it was mostly scraped out. I know that my stroke is a bit too long, I have been working on that.

My scraper is homemade from about two years ago when I was shorter and did not have a mill, I lengthened it but I will remake it better. It is made from 1/8 x 1” I checked with one of Richard’s students and he said it has the right amount of flex. The blade was ground by the same student and he gave it to me. It has a 60mm and 90mm radius ground into it. I just built a diamond lapper, RPM is about 620 and I have a negative 5 degree rake to avoid micro fractures. It currently has a 3,000 grit wheel on it to hone the blade.

I scrape at a 45 degree angle to a side and switch directions each time I blue it. (If I scraped from the bottom left towards the top right, the next time I would scrape from the bottom right to the top left.) I used my body to push the scraper. It has a large furniture pad to distribute the force. When I scrape there is no chatter.

When I scrape I aim to remove a small blue spot or cut a medium one in half and get half high half low on the big spots. When I am done I brush off all the chips then use a stone to knock down the burrs. I then wipe it all down with acetone and repeat.

This is about my 15th blue, there was a 1.5 thou dish when I started. I have scraped it for 10 hours so far

Now the sides are a bit low with a few small low spots elsewhere. The corners at an even height to the center now.

Hello, I have only been taught for a couple of hours how to scrape, the rest is reading and YouTube. I am trying to get better at scraping to scrape in my metal planer.

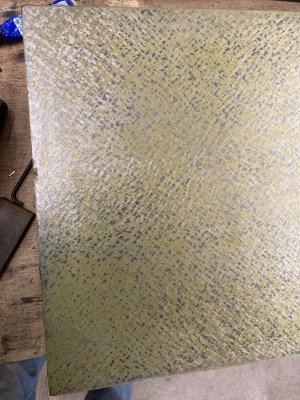

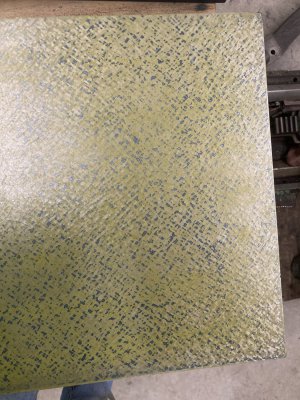

My surface plate is a 10”x12” Chinese A grade that had its own “certificate”. I use dykem high spot blue as the ink and a speed ball roller. I put the ink on a sheet of glass then transfer it to the surface plate. I then wipe down both surface plates with my hand to get rid of any dust. Lift up the inked one, flip it over and lower it on the cast iron plate (15”x18”). I move the granite plate around on the cast iron plate making sure to not got over an inch off the edges. I already checked for dishing and doming with feeler gauges and it was mostly scraped out. I know that my stroke is a bit too long, I have been working on that.

My scraper is homemade from about two years ago when I was shorter and did not have a mill, I lengthened it but I will remake it better. It is made from 1/8 x 1” I checked with one of Richard’s students and he said it has the right amount of flex. The blade was ground by the same student and he gave it to me. It has a 60mm and 90mm radius ground into it. I just built a diamond lapper, RPM is about 620 and I have a negative 5 degree rake to avoid micro fractures. It currently has a 3,000 grit wheel on it to hone the blade.

I scrape at a 45 degree angle to a side and switch directions each time I blue it. (If I scraped from the bottom left towards the top right, the next time I would scrape from the bottom right to the top left.) I used my body to push the scraper. It has a large furniture pad to distribute the force. When I scrape there is no chatter.

When I scrape I aim to remove a small blue spot or cut a medium one in half and get half high half low on the big spots. When I am done I brush off all the chips then use a stone to knock down the burrs. I then wipe it all down with acetone and repeat.

This is about my 15th blue, there was a 1.5 thou dish when I started. I have scraped it for 10 hours so far

Now the sides are a bit low with a few small low spots elsewhere. The corners at an even height to the center now.