- Joined

- Nov 13, 2013

- Messages

- 104

Hello

I picked up a rather neglected 9A. Everything from the gears, quick change gear box and apron were filled/packed with grease and particulate (twas a mess)

Disassembled, cleaned with kerosene and reassembled. I've acquired all of the recommended oils and lubes. All good so far.

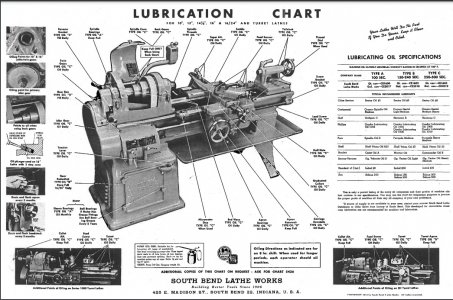

Even after looking at the lube chart I am still confused.........My question is,

what lubricant is applied externally (topically) to the dry gears and internals of the apron?

Thank you again

I picked up a rather neglected 9A. Everything from the gears, quick change gear box and apron were filled/packed with grease and particulate (twas a mess)

Disassembled, cleaned with kerosene and reassembled. I've acquired all of the recommended oils and lubes. All good so far.

Even after looking at the lube chart I am still confused.........My question is,

what lubricant is applied externally (topically) to the dry gears and internals of the apron?

Thank you again