- Joined

- Jan 29, 2014

- Messages

- 156

First set of cutters arrived today.

I do have a couple of small B&S cutters that appear to be unused. Comparing the two:

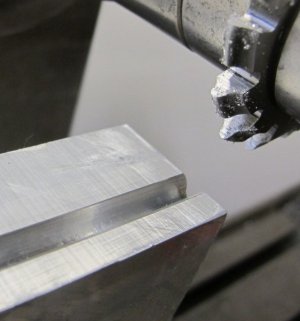

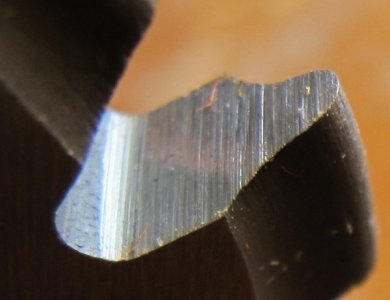

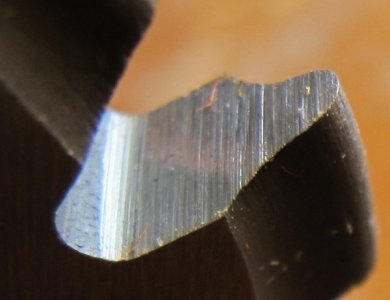

The import tooth grind:

The B&S tooth grind:

The grind shaping the tooth and tooth face seem to have the same quality. At least as far as the roughness.

Unfortunately I have to turn an arbor to use these with my milling machine. So I will have to provide an update on how they cut at a later date.

I also ordered some cutters from another vendor that appear to come from a different factory. Those were even less expensive. I will provide some pictures when they arrive.

I do have a couple of small B&S cutters that appear to be unused. Comparing the two:

- The B&S has 12 teeth and the Import 14

- The B&S has a 7/8" bore, the Import 22mm

- I believe the B&S has the depth of cut stamped on it (.180"), the import does not. No paperwork with the cutters, not quite sure if this is standard value or not.

- The engraving on the import does not look very deep. I will need to give some thought to how I keep track of these if the markings wear off.

- As mentioned elsewhere the B&S #1 is 135 to rack and the import #1 is 12-13 teeth. I think I will be able to not confuse the cutters and find the correct one for the job.

- I will not be able to sharpen the import as often as I can the B&S, but I don't plan on living long enough for that to be an issue.

The import tooth grind:

The B&S tooth grind:

The grind shaping the tooth and tooth face seem to have the same quality. At least as far as the roughness.

Unfortunately I have to turn an arbor to use these with my milling machine. So I will have to provide an update on how they cut at a later date.

I also ordered some cutters from another vendor that appear to come from a different factory. Those were even less expensive. I will provide some pictures when they arrive.

Last edited: