- Joined

- Nov 19, 2011

- Messages

- 966

thats a great idea too ty for the info:biggrin:HI

I normaly measure a bolt of the same size and turn the bar to that size .

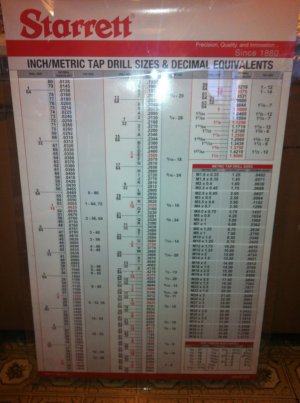

If you want the tapping size for a hole, and you dont have the charts to hand ,find a drill that fits the inside of a nut of the size you want

I know this advice is crude, but when needs must, it works.

Regards BRIAN.