- Joined

- Jun 7, 2019

- Messages

- 466

A friend of mine has a little 11” Rockwell lathe with a worn out apron drive gear. Apparently they are unobtanium, unless you find a NOS one for big bucks. So let’s make one!

It’s a 36 tooth DP16 worm gear made from bronze. It also functions as the cone clutch. After a good bit of research, I’ve verified the original gear wasn’t hobbed. It is a simple helical cut gear as the worm wheel. I’d guess that’s why they are all worn out. Point contact between the worm and the wheel tooth when new. Anyhow, that makes it much easier to replicate. Measured up the original and drew up the blank. Calculated all the tooth data necessary and made a test blank out of aluminum for a test run. Set up my Deckel dividing head with a custom made arbor matching to the cone taper of the gear on the Bridgeport. The finished practice gear fits up perfectly in the apron. Now waiting for the crazy expensive bearing bronze to make the real gear now that everything is validated. Probably make 2 or 3 of these while I’m set up.

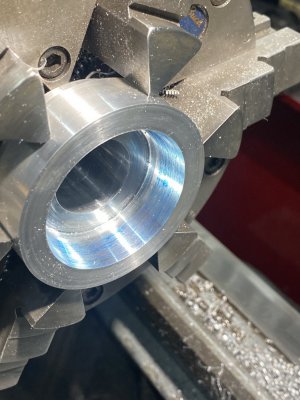

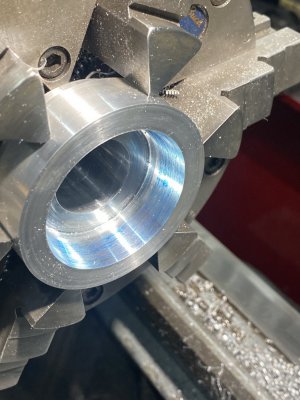

blue check on clutch taper.

milling setup

Old bronze and aluminum practice gear. You can see 2/3 of the tooth is worn away on the bronze gear.

It’s a 36 tooth DP16 worm gear made from bronze. It also functions as the cone clutch. After a good bit of research, I’ve verified the original gear wasn’t hobbed. It is a simple helical cut gear as the worm wheel. I’d guess that’s why they are all worn out. Point contact between the worm and the wheel tooth when new. Anyhow, that makes it much easier to replicate. Measured up the original and drew up the blank. Calculated all the tooth data necessary and made a test blank out of aluminum for a test run. Set up my Deckel dividing head with a custom made arbor matching to the cone taper of the gear on the Bridgeport. The finished practice gear fits up perfectly in the apron. Now waiting for the crazy expensive bearing bronze to make the real gear now that everything is validated. Probably make 2 or 3 of these while I’m set up.

blue check on clutch taper.

milling setup

Old bronze and aluminum practice gear. You can see 2/3 of the tooth is worn away on the bronze gear.