- Joined

- Dec 29, 2012

- Messages

- 394

A friend of mine seeks a Power Supply Unit (PSU) capable of 13.8V at 50 Amps. As the ready-made ones are a) rather expensive and b) unreliable (Chinese) he asked if I could make one for him.

I love challenges and I could not resist this one! So I sought information on Low voltage High current PSUs.

I found out that the most expensive part to make a high current PSU is the transformer as you need at least 800Watt power out of it! Thank God there are plenty of 800 watt transformers available for free in old microwave ovens. In a day I found a microwave unit with an as-good-as-new transformer.

These transformers have a 230V (Europe) thick wire primary and 2000V thin wire secondary to produce the high voltage needed for the microwave magnetron!

As I only need the primary I cut and removed the secondary using my hammer and an old wood chisel.

After removing the secondary wires (hammering them out of the transformer) I had a transformer body with a primary winding ready to accept my new High Current-Low voltage secondary.

I started by winding 5 turns of an insulated piece of wire for a secondary and after connecting the primary to mains I measured the voltage it gives. It gave 4.5V AC. That means my transformer’s secondary winding gives 0.9 Volts per turn.

Then it was easy to calculate the number of windings for the needed voltage.

I needed a voltage around 16 Volts (to have a margin for rectification diode drops) so 17 to 18 turns were enough.

Next thing was the calculation of wire thickness.

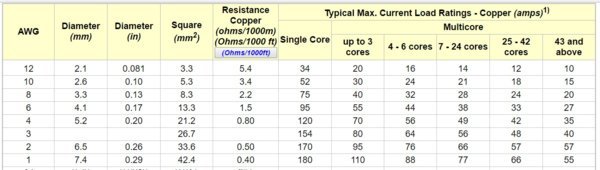

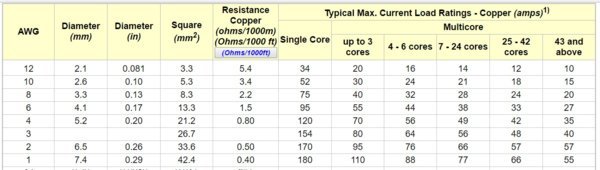

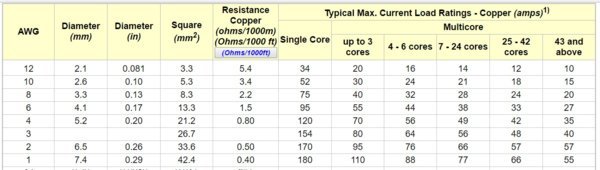

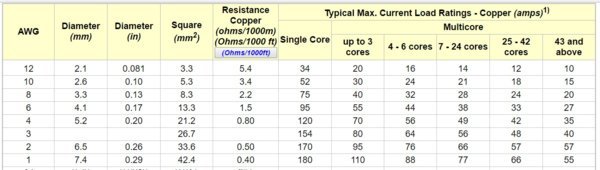

I need a wire capable of 60 Amps to play safe, so I consulted the AWG tables to have an idea of proper thicknesses.

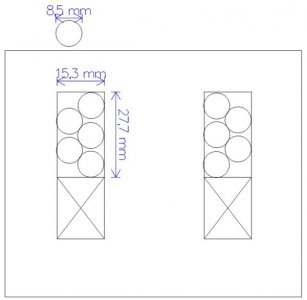

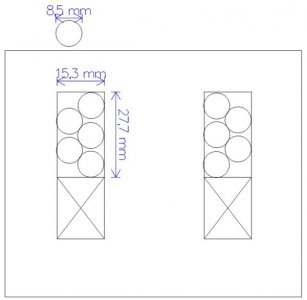

The closest wire, suitable for my needs, was a 7core 2 AWG (6,5mm) capable of 66A. With 1mm insulation the wire was 8.5mm diameter, too thick to be of use for the transformer I had!

It would have space just for 5 turns giving, as per test wires, 5 x 0,9 = 4,5 Volts!!!!

A different approach needed that:

1 would make use of all available space without any air gaps

2. give me the 17 to 18 turns I need for the voltage

3. make use of material I already have

I have inherited a few copper sheets 200 x 60 cm and 0.6mm thick that collect dust for more than 30 years in the basement. So I calculated if strips from the copper sheets could be used to rewind the secondary.

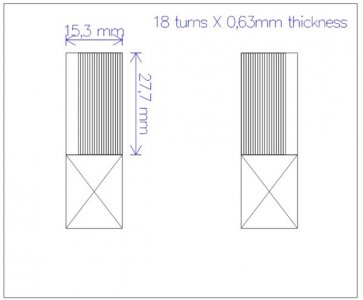

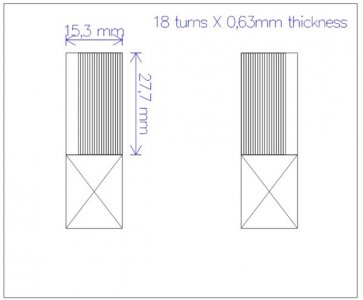

Some calculations later, I estimated that the 0,6mm thickness strip will be more than adequate for my needs, As:

a) Fits in the required space

b) Is capable to withstand some 100Amps (26.5 x 0.6 = 15.9 mm^2, better than 1 core 6AWG as you can see below)

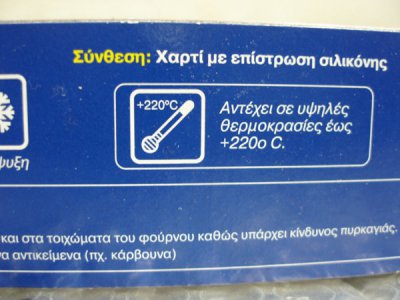

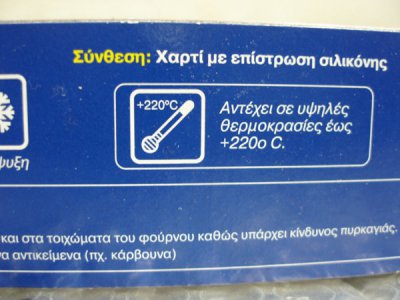

Apart from the copper strips I needed some heat resisting insulation to put between the strips. I found the best insulating material in my wife's kitchen. It is a roll of “silicon impregnated non stick oven paper” (I don’t know the proper english name of it)!

It withstands temperatures up to 220 C, it is very strong although it has a thickness of 0.04mm, so I will put 4 layers of it just to play safe.

Next step was to cut the foil in 27mm strips. That was done with some help from my trusty mini lathe, a steel core and a razor blade.

How much length of copper I needed?

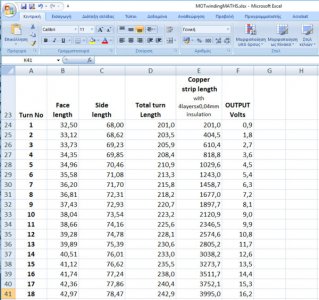

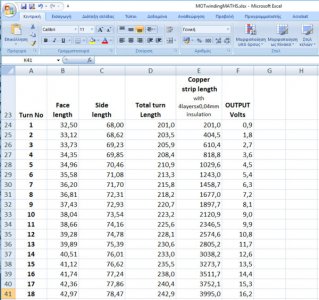

Calculating the core of the transformer and adding the thickness of each strip together with its insulation made a nice spreadsheet with all the details.

To cut the copper strips I used an old drill powered sheet metal cutter.

Not the best way to do it but it did the job with just a few areas to file.

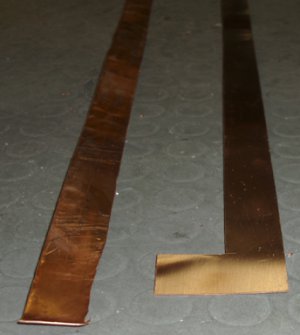

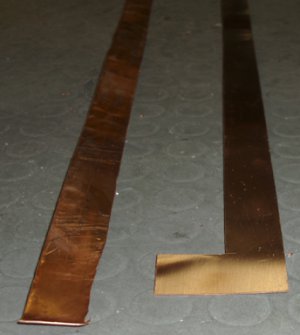

Two strips 2m x 26.5 mm after an hour of measuring, marking and cutting were lying on the floor.

The right angle extension marks the starting point of the “wire” to make the connections later.

Rewinding was a matter of careful folding the copper strip over the 4 insulation strips around the center of the transformer.

Wooden wedges helped pressing the sides to keep the windings from unfolding

An hour or so later the first 2 meters strip was in place.

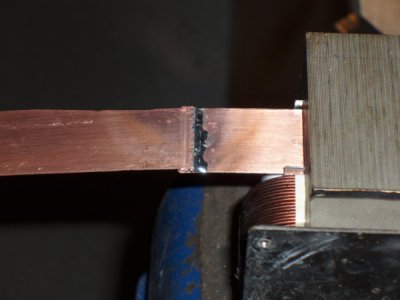

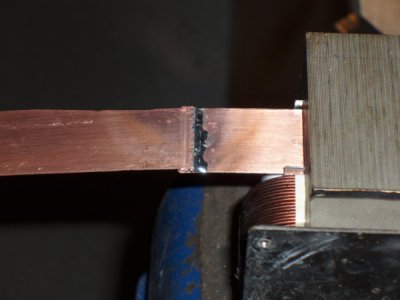

Time to folder and solder the next one.

Another hour or so the rewinding finished, new windings were tested for continuity, short circuits etc. and as the results were fine, Coil winding “cool cure” varnish poured throughout the windings and the transformer was ready.

Transformer back side after varnishing.

Transformer front side. You can see start and finish ends of the secondary high current coil.

At the bottom the 2 wires that go to mains, to test the transformer

Testing the transformer a few hours later. All is OK.

15.63 Volts AC

Plenty of Current also (estimated around 50 Amps)!

Unfortunately my 100A amp meter is on its way from far east and I do not have the equipment to measure the amps produced.

A 40 amps circuit breaker connected to the secondary, goes off instantly while I short the low voltage circuit through it.

Waiting for the rest of the parts to arrive from China to construct the PSU I will leave the transformer in peace for the next weeks!

Thanks for reading.

Petros

I love challenges and I could not resist this one! So I sought information on Low voltage High current PSUs.

I found out that the most expensive part to make a high current PSU is the transformer as you need at least 800Watt power out of it! Thank God there are plenty of 800 watt transformers available for free in old microwave ovens. In a day I found a microwave unit with an as-good-as-new transformer.

These transformers have a 230V (Europe) thick wire primary and 2000V thin wire secondary to produce the high voltage needed for the microwave magnetron!

As I only need the primary I cut and removed the secondary using my hammer and an old wood chisel.

After removing the secondary wires (hammering them out of the transformer) I had a transformer body with a primary winding ready to accept my new High Current-Low voltage secondary.

I started by winding 5 turns of an insulated piece of wire for a secondary and after connecting the primary to mains I measured the voltage it gives. It gave 4.5V AC. That means my transformer’s secondary winding gives 0.9 Volts per turn.

Then it was easy to calculate the number of windings for the needed voltage.

I needed a voltage around 16 Volts (to have a margin for rectification diode drops) so 17 to 18 turns were enough.

Next thing was the calculation of wire thickness.

I need a wire capable of 60 Amps to play safe, so I consulted the AWG tables to have an idea of proper thicknesses.

The closest wire, suitable for my needs, was a 7core 2 AWG (6,5mm) capable of 66A. With 1mm insulation the wire was 8.5mm diameter, too thick to be of use for the transformer I had!

It would have space just for 5 turns giving, as per test wires, 5 x 0,9 = 4,5 Volts!!!!

A different approach needed that:

1 would make use of all available space without any air gaps

2. give me the 17 to 18 turns I need for the voltage

3. make use of material I already have

I have inherited a few copper sheets 200 x 60 cm and 0.6mm thick that collect dust for more than 30 years in the basement. So I calculated if strips from the copper sheets could be used to rewind the secondary.

Some calculations later, I estimated that the 0,6mm thickness strip will be more than adequate for my needs, As:

a) Fits in the required space

b) Is capable to withstand some 100Amps (26.5 x 0.6 = 15.9 mm^2, better than 1 core 6AWG as you can see below)

Apart from the copper strips I needed some heat resisting insulation to put between the strips. I found the best insulating material in my wife's kitchen. It is a roll of “silicon impregnated non stick oven paper” (I don’t know the proper english name of it)!

It withstands temperatures up to 220 C, it is very strong although it has a thickness of 0.04mm, so I will put 4 layers of it just to play safe.

Next step was to cut the foil in 27mm strips. That was done with some help from my trusty mini lathe, a steel core and a razor blade.

How much length of copper I needed?

Calculating the core of the transformer and adding the thickness of each strip together with its insulation made a nice spreadsheet with all the details.

To cut the copper strips I used an old drill powered sheet metal cutter.

Not the best way to do it but it did the job with just a few areas to file.

Two strips 2m x 26.5 mm after an hour of measuring, marking and cutting were lying on the floor.

The right angle extension marks the starting point of the “wire” to make the connections later.

Rewinding was a matter of careful folding the copper strip over the 4 insulation strips around the center of the transformer.

Wooden wedges helped pressing the sides to keep the windings from unfolding

An hour or so later the first 2 meters strip was in place.

Time to folder and solder the next one.

Another hour or so the rewinding finished, new windings were tested for continuity, short circuits etc. and as the results were fine, Coil winding “cool cure” varnish poured throughout the windings and the transformer was ready.

Transformer back side after varnishing.

Transformer front side. You can see start and finish ends of the secondary high current coil.

At the bottom the 2 wires that go to mains, to test the transformer

Testing the transformer a few hours later. All is OK.

15.63 Volts AC

Plenty of Current also (estimated around 50 Amps)!

Unfortunately my 100A amp meter is on its way from far east and I do not have the equipment to measure the amps produced.

A 40 amps circuit breaker connected to the secondary, goes off instantly while I short the low voltage circuit through it.

Waiting for the rest of the parts to arrive from China to construct the PSU I will leave the transformer in peace for the next weeks!

Thanks for reading.

Petros

Last edited: