Hopefully I've researched enough to have the proper answer, but I'm hesitant enough so I'll ask to be sure.

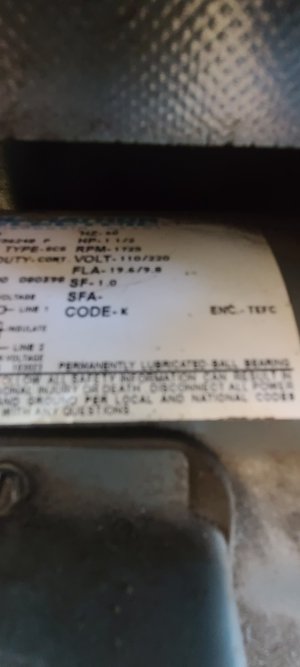

ENCO 110-1351- WAS working, until I decided to "fix" it. By fix it, I mean removed nearly everything inside the electrical panel chasing down an issue.

End result- bad contactor. It was stuck pulled in (melted contacts). Found the offending item on Amazon for $18. So, as always, ordered 3. If one goes bad, the others aren't far behind. On a 25 year old machine, I'd rather be safe than sorry, especially for $60.

Now. As I patiently await the mailman, I had a thought.

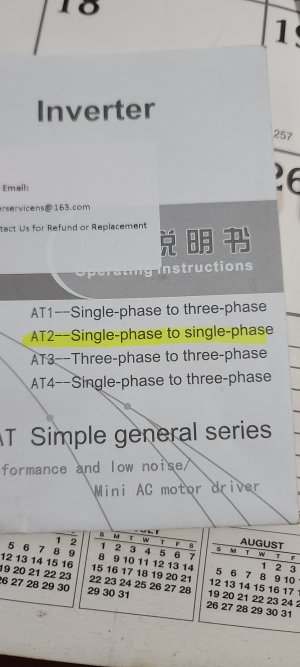

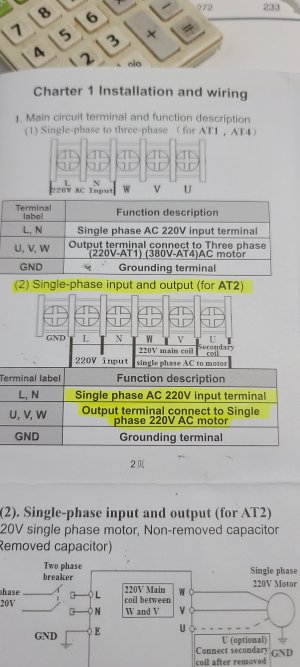

Why not ditch the switching gear with a VFD? The one I installed yesterday was so easy, and it appears there's nearly infinite control, wouldn't it make sense to wire direct to the motor with a new VFD? Hypothetically, removing all the contactors, relays, heating relay, and transformer simplifies the electrical. The VFD could control forward and reverse, the speeds are controlled by voltage/hertz.

Just wondering if others have done the same just to simplify the system. As I'm still VERY new to this, I don't want to be the new guy who rushes headfirst into the fray, only to discover that others have made the same decisions, and failed.

Read multiple threads where guys have done this same thing, (albeit different machines), but in my small mind, having a VFD mounted after the plug, and before the motor would negate all the other controls.

VFD should control forward/reverse. Simple E-Stop could stop power. Don't know if I could low voltage control with the apron switch or not, but maybe....

Yes? No? Leave it alone, and just reinstall the contactor that'll be here today?

I'm just thinking that a $90 VFD could alleviate any future wiring issues.

ENCO 110-1351- WAS working, until I decided to "fix" it. By fix it, I mean removed nearly everything inside the electrical panel chasing down an issue.

End result- bad contactor. It was stuck pulled in (melted contacts). Found the offending item on Amazon for $18. So, as always, ordered 3. If one goes bad, the others aren't far behind. On a 25 year old machine, I'd rather be safe than sorry, especially for $60.

Now. As I patiently await the mailman, I had a thought.

Why not ditch the switching gear with a VFD? The one I installed yesterday was so easy, and it appears there's nearly infinite control, wouldn't it make sense to wire direct to the motor with a new VFD? Hypothetically, removing all the contactors, relays, heating relay, and transformer simplifies the electrical. The VFD could control forward and reverse, the speeds are controlled by voltage/hertz.

Just wondering if others have done the same just to simplify the system. As I'm still VERY new to this, I don't want to be the new guy who rushes headfirst into the fray, only to discover that others have made the same decisions, and failed.

Read multiple threads where guys have done this same thing, (albeit different machines), but in my small mind, having a VFD mounted after the plug, and before the motor would negate all the other controls.

VFD should control forward/reverse. Simple E-Stop could stop power. Don't know if I could low voltage control with the apron switch or not, but maybe....

Yes? No? Leave it alone, and just reinstall the contactor that'll be here today?

I'm just thinking that a $90 VFD could alleviate any future wiring issues.

Last edited: