Hi all,

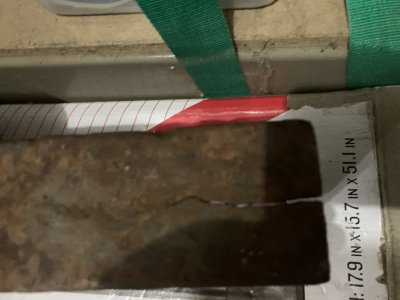

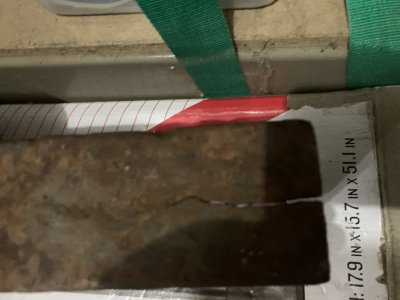

This is my first post. I am a glutton for punishment who gets joy out of repairing tools. So, I bought an old Prentiss Bulldog vise that has seen better days. There is a crack in the slide of about 4” and part of the casting is missing on the fixed jaw side.

There is a lot of good information online about brazing the crack in the slide. I’m also wondering if it would be possible to build up the missing casting with bronze brazing. Alternatively, I was thinking that the broken casting could be machined/milled to accept a piece of mild steel that would be brazed into place. Curious what folks think about these options?

The catch is I am interested in learning machinist skills but I don’t have a shop or any tools to accomplish these repairs. I was wondering if there was anyone in Chicagoland or within a reasonable drive who is capable of doing the repairs to the vise and whom I could learn from (of course, I would pay for the worn but also would like to learn at the same time).

Thanks,

Paul

This is my first post. I am a glutton for punishment who gets joy out of repairing tools. So, I bought an old Prentiss Bulldog vise that has seen better days. There is a crack in the slide of about 4” and part of the casting is missing on the fixed jaw side.

There is a lot of good information online about brazing the crack in the slide. I’m also wondering if it would be possible to build up the missing casting with bronze brazing. Alternatively, I was thinking that the broken casting could be machined/milled to accept a piece of mild steel that would be brazed into place. Curious what folks think about these options?

The catch is I am interested in learning machinist skills but I don’t have a shop or any tools to accomplish these repairs. I was wondering if there was anyone in Chicagoland or within a reasonable drive who is capable of doing the repairs to the vise and whom I could learn from (of course, I would pay for the worn but also would like to learn at the same time).

Thanks,

Paul