Hey all,

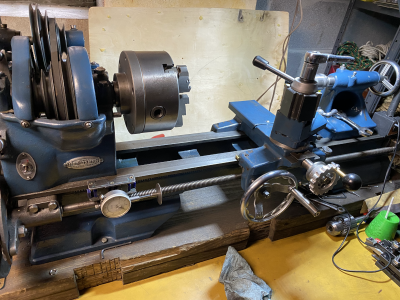

I have a 1930's Craftsman / Atlas lathe as per photo

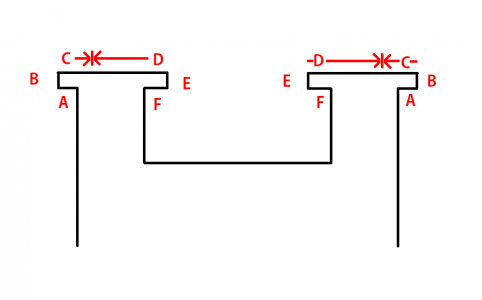

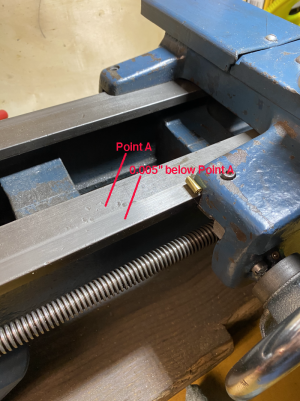

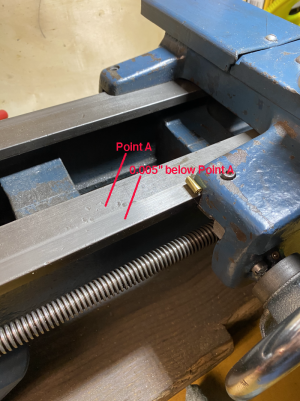

The saddle is constructed such that it rides on the outside of the flat ways and, as expected, in the area of most use, it has worn down, as per photo.

This does two things: 1) It allows the carriage to drop a bit lower, decreasing the engagement of my feed gear into the gear rack under the ways (not shown), which increases backlash slop in the feed wheel. I could live with this, but it is a bit annoying. To address this, I have put 0.010" shim under the carriage (see rolled end in the photo) which helps some.

But the second issue is that I can't adjust my carriage gibs etc in well enough get rigidity at my tool point. This is especially evident when trying to do single-point thread cutting. I can often move the tip at least 10 thousandths with just my hand. And if I try to tighten everything up, then the carriage sticks at the point of less wear.

To fix this, I think I have a few options

1) Send ways off to be ground flat.

2) Scrape the ways flat down to the lowest point.

3) Build up the worn area and then scrape flat

I'd like to explore option 3 (building up) first.

Searching this forum, I have found mention of Loctite Fixmaster Metal Rebuilding. (

) which seems to come as a liquid or putty. And then there is Turcite and Rulon which seem to come as sheets that are glued down.

Questions:

1) It seems that any type of epoxy is going to have a hard time adhering when it is so thin, i.e. 5 thou'. So would I need to abrade the surface with grooves to increase adherence?

2) For the Turcite strips, It seems they would adhere to the surface better. But can the withstand the scraping action that the saddle will place on it? Seems like I have heard that Turcite is much softer (and thus easier to scrape) than metal. So does it wear faster? And how thin are the strips. Would I have to lower my surface, which is currently 5 thou' down, to 10-20 thou'?

Thanks in advance for any advice.

Kevin T

I have a 1930's Craftsman / Atlas lathe as per photo

The saddle is constructed such that it rides on the outside of the flat ways and, as expected, in the area of most use, it has worn down, as per photo.

This does two things: 1) It allows the carriage to drop a bit lower, decreasing the engagement of my feed gear into the gear rack under the ways (not shown), which increases backlash slop in the feed wheel. I could live with this, but it is a bit annoying. To address this, I have put 0.010" shim under the carriage (see rolled end in the photo) which helps some.

But the second issue is that I can't adjust my carriage gibs etc in well enough get rigidity at my tool point. This is especially evident when trying to do single-point thread cutting. I can often move the tip at least 10 thousandths with just my hand. And if I try to tighten everything up, then the carriage sticks at the point of less wear.

To fix this, I think I have a few options

1) Send ways off to be ground flat.

2) Scrape the ways flat down to the lowest point.

3) Build up the worn area and then scrape flat

I'd like to explore option 3 (building up) first.

Searching this forum, I have found mention of Loctite Fixmaster Metal Rebuilding. (

Questions:

1) It seems that any type of epoxy is going to have a hard time adhering when it is so thin, i.e. 5 thou'. So would I need to abrade the surface with grooves to increase adherence?

2) For the Turcite strips, It seems they would adhere to the surface better. But can the withstand the scraping action that the saddle will place on it? Seems like I have heard that Turcite is much softer (and thus easier to scrape) than metal. So does it wear faster? And how thin are the strips. Would I have to lower my surface, which is currently 5 thou' down, to 10-20 thou'?

Thanks in advance for any advice.

Kevin T