- Joined

- Nov 24, 2012

- Messages

- 18

I've been looking out for a BP or clone to CNC for a few years and ran across this BOSS 10 V2E3 by chance. Essentially a series I machine factory converted to CNC. Machines around here seem to go for astronomical costs relative to the prices I see posted around the forums. A functioning manual machine in good shape will sell between $3k to $5k when they pop up and that is once in a blue moon. I didn't hesitate to fork over the $1k this guy was asking. All of the thirty year old control boards and modules haven been ripped out of the machine. With some luck I may get my money back selling them on fleabay.

The only issue is the quill is stuck. Since all the ways are good and the machine is already outfitted with ball screws and servos I am still ahead of the game even if the head needs major work or swapped with something else. Still haven't decided how to approach it yet. After mustering up enough courage to tear it down I might be leaning on you guys for a little guidance )

)

Now for some pictures...

Fresh off the trailer

Enclosures ripped and stripped

Original condition of the table

Table after lots of WD40, copper scrubbies, and elbow grease. Don't think that vice moved for the better part of a decade.

Y ways before

Y ways after

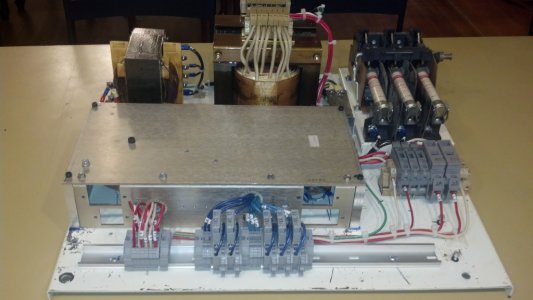

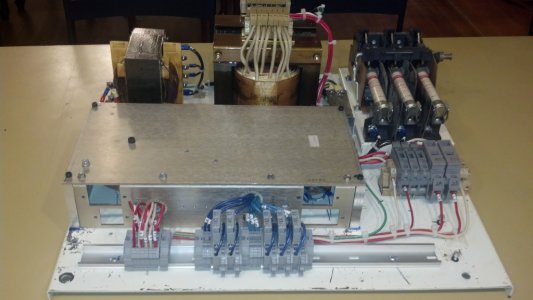

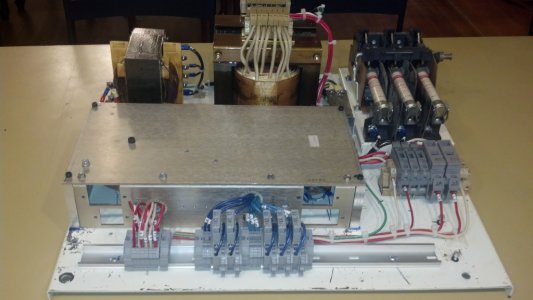

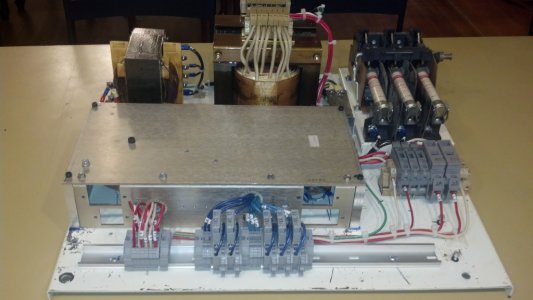

Power panel rewired and mocked up. Cap bank came from a large scrapped VFD a customer was pitching.

The original rack mounted DC power supply mounted and reconfigured sans connectors.

More to follow when I get a round tuit.

The only issue is the quill is stuck. Since all the ways are good and the machine is already outfitted with ball screws and servos I am still ahead of the game even if the head needs major work or swapped with something else. Still haven't decided how to approach it yet. After mustering up enough courage to tear it down I might be leaning on you guys for a little guidance

Now for some pictures...

Fresh off the trailer

Enclosures ripped and stripped

Original condition of the table

Table after lots of WD40, copper scrubbies, and elbow grease. Don't think that vice moved for the better part of a decade.

Y ways before

Y ways after

Power panel rewired and mocked up. Cap bank came from a large scrapped VFD a customer was pitching.

The original rack mounted DC power supply mounted and reconfigured sans connectors.

More to follow when I get a round tuit.