-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Redlineman's Logan 200 Rescue

- Thread starter Redlineman

- Start date

- Joined

- Jul 27, 2013

- Messages

- 295

WOW!

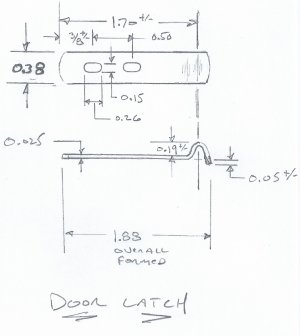

Lot's of fuss over a latch! I had figured what it was supposed to be, knew that they were not shown in the prints, that originals were not common at all, nor available new. I just wanted to see one for real. I had thought of spring steel like the original, a toggle latch, and I like the magnet idea, except for the empty holes left behind. I'll decide on something by and by.

Lot's of fuss over a latch! I had figured what it was supposed to be, knew that they were not shown in the prints, that originals were not common at all, nor available new. I just wanted to see one for real. I had thought of spring steel like the original, a toggle latch, and I like the magnet idea, except for the empty holes left behind. I'll decide on something by and by.

- Joined

- Jul 27, 2013

- Messages

- 295

-

Trudging along.

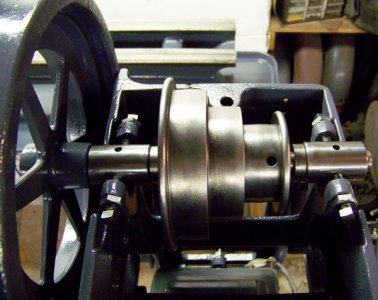

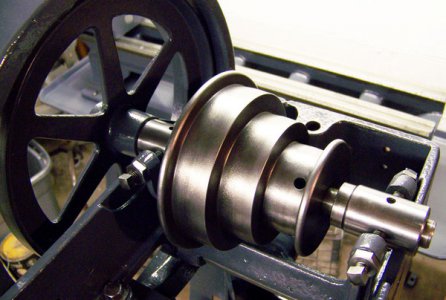

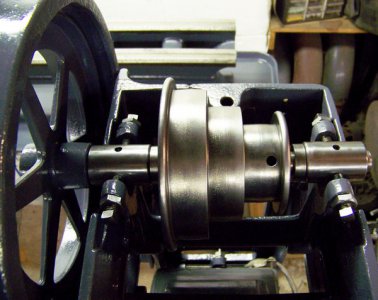

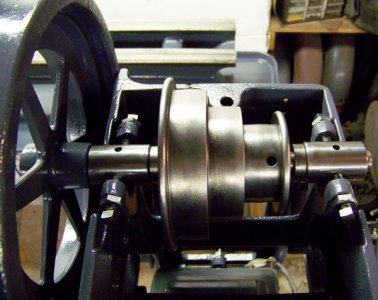

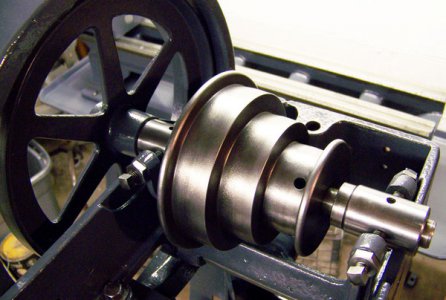

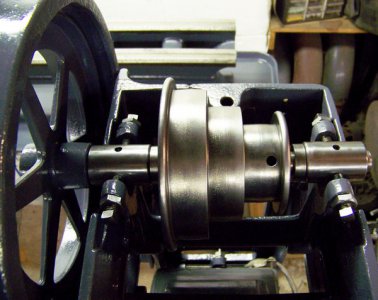

Dry run on the primary drive unit. Learning how it all goes together. Taking something apart, and even taking a lot of pics, is no assurance that you will understand the nuances of how it needs to be to function properly. My photos and the schematics told me where things went, but not how, and there is a definite how to this early system. The locating pins on either side of the bushing collars cannot be tightened nearly as tight as you might expect or assume. The proper tension is surprisingly light, taking very little more than finger tightening to start to actually bind the shaft. Not what I expected. Probably over complicated in some sense, compared to the later unitized arrangement, but I sort of like the relative complexity, which I find slightly elegant. There may even be some advantage, although I have not discovered it yet if there is.

The real reason for this trial run on the primary was to see where I stood in the pulley department. You can see the incorrect adjustable width pulley that was on it prior to my teardown. I needed to get a sense of whether the motor shaft was long enough to set the pulleys in the right position, and if there was room for the proper double pulley to fit the shaft. With this pulley flush on the end of the motor shaft, it is pretty well aligned with its mate on the big end, and there is room to the inside for the small pulley. The previous belt is marked 5L520R, which I assume is 52", and adjusting it revealed it to be too long for the job; the belt rubbing on the bottom of the guard frame when well tensioned. Logan calls for an LA-388 51" belt, and I'll very likely use a 4L instead. With this fit information I can work on my pulley solution, whose direction is uncertain at this point. More projects...

Trudging along.

Dry run on the primary drive unit. Learning how it all goes together. Taking something apart, and even taking a lot of pics, is no assurance that you will understand the nuances of how it needs to be to function properly. My photos and the schematics told me where things went, but not how, and there is a definite how to this early system. The locating pins on either side of the bushing collars cannot be tightened nearly as tight as you might expect or assume. The proper tension is surprisingly light, taking very little more than finger tightening to start to actually bind the shaft. Not what I expected. Probably over complicated in some sense, compared to the later unitized arrangement, but I sort of like the relative complexity, which I find slightly elegant. There may even be some advantage, although I have not discovered it yet if there is.

The real reason for this trial run on the primary was to see where I stood in the pulley department. You can see the incorrect adjustable width pulley that was on it prior to my teardown. I needed to get a sense of whether the motor shaft was long enough to set the pulleys in the right position, and if there was room for the proper double pulley to fit the shaft. With this pulley flush on the end of the motor shaft, it is pretty well aligned with its mate on the big end, and there is room to the inside for the small pulley. The previous belt is marked 5L520R, which I assume is 52", and adjusting it revealed it to be too long for the job; the belt rubbing on the bottom of the guard frame when well tensioned. Logan calls for an LA-388 51" belt, and I'll very likely use a 4L instead. With this fit information I can work on my pulley solution, whose direction is uncertain at this point. More projects...

That assembly is coming along nicely.

As to the belt, the one laying on my shelf says 4L410 and it appears to fit the pulley nicely.

As to the OEM pulley, mine is clearly size 4. OD on large pulley is about 4-1/4 inch, OD on smaller one is about 2-5/16 inch. It looks like the two pulley grooves are on about 3/4 inch centers, so you may need some spacers if you're putting something together.

Good luck.

As to the belt, the one laying on my shelf says 4L410 and it appears to fit the pulley nicely.

As to the OEM pulley, mine is clearly size 4. OD on large pulley is about 4-1/4 inch, OD on smaller one is about 2-5/16 inch. It looks like the two pulley grooves are on about 3/4 inch centers, so you may need some spacers if you're putting something together.

Good luck.

- Joined

- Jul 27, 2013

- Messages

- 295

Thank guys;

Toag, I'm just cleaning, painting, and reassembling, that's all. The bling has yet to come! I'm going to have a little fun here and there. Thanks for the support, from you and everyone!

I'm going to have a little fun here and there. Thanks for the support, from you and everyone!

This is a pic of the one that Logan sells as a replacement for the 11" models. It does not have to proper sizes for the 10" models according to what they had new. They also list the correct smaller size, but show no pic. I can only assume it is similar. I don't begrudge them their profit, and as someone else said somewhere, I'm sure they are not getting rich selling Logan parts. However, $130 has to go a long way in my world. I'll be ordering sheaves and a belt from Surplus Center today. All in around $20 + shipping!

Toag, I'm just cleaning, painting, and reassembling, that's all. The bling has yet to come!

This is a pic of the one that Logan sells as a replacement for the 11" models. It does not have to proper sizes for the 10" models according to what they had new. They also list the correct smaller size, but show no pic. I can only assume it is similar. I don't begrudge them their profit, and as someone else said somewhere, I'm sure they are not getting rich selling Logan parts. However, $130 has to go a long way in my world. I'll be ordering sheaves and a belt from Surplus Center today. All in around $20 + shipping!

The last time I needed a motor drive pulley, I ended up making one. Like you said, 130.00 is way too much to invest in a pulley for a lathe project. 4" diameter alum isn't cheap either but you don't need much of it. For me the toughest part is broaching a decent keyway. I don't have a set of broaches. I would think if you're patient someone should be able to come up with the pulley you need....for a lot less than 130.00. I'll keep searching through my drawers and shelves.

Chuck

Chuck

- Joined

- Jul 27, 2013

- Messages

- 295

Again;

I don't begrudge Logan a fair profit, and if I was made of money it would not be an issue and I'd get "the real thing" and support their existence. It probably cost them quite a lot to have those made, even with automated processes. I am always tempted to make things instead of buy, but I would need to buy a bunch of tools that I don't have just to even make one. Six o'one, half dozen o'tuther. For $24 I bought two sheaves and a belt from Surplus Center. I can imagine having to dink around with the pulleys to get the spacing right, but I think I can git'r dun. The sheaves are not exactly the correct OD, but I guess close is close enough.

I don't begrudge Logan a fair profit, and if I was made of money it would not be an issue and I'd get "the real thing" and support their existence. It probably cost them quite a lot to have those made, even with automated processes. I am always tempted to make things instead of buy, but I would need to buy a bunch of tools that I don't have just to even make one. Six o'one, half dozen o'tuther. For $24 I bought two sheaves and a belt from Surplus Center. I can imagine having to dink around with the pulleys to get the spacing right, but I think I can git'r dun. The sheaves are not exactly the correct OD, but I guess close is close enough.