- Joined

- Sep 8, 2019

- Messages

- 4,392

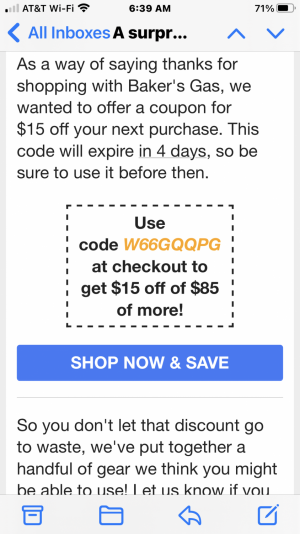

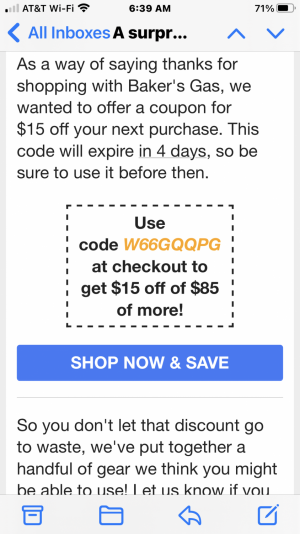

I have a coupon code (and so do you, see below). I have no magnetic squares. Any recommendations?

I have used the cheap red ones at schools. They were well used (burnt & had a lot of iron filings sticking to them). My welding fixtures do seem to get torched & well used.

I am wondering if I should pay more for the On/Off magnetic squares. I wonder if they need batteries *or* if they work like a mag base.

I do a lot of .125” thick, 3” X 4” welding coupons. My current project is 1” square tubing. The next project is a very heavy duty 5/8” plate cart.

I don’t anticipate being able to use the same magnetic squares for the sheet coupons as for the 5/8” plate.

Do you think that I could make do with small & large cheap red ones like this?

I have used the cheap red ones at schools. They were well used (burnt & had a lot of iron filings sticking to them). My welding fixtures do seem to get torched & well used.

I am wondering if I should pay more for the On/Off magnetic squares. I wonder if they need batteries *or* if they work like a mag base.

I do a lot of .125” thick, 3” X 4” welding coupons. My current project is 1” square tubing. The next project is a very heavy duty 5/8” plate cart.

I don’t anticipate being able to use the same magnetic squares for the sheet coupons as for the 5/8” plate.

Do you think that I could make do with small & large cheap red ones like this?