- Joined

- Nov 16, 2012

- Messages

- 5,596

Excellent thread top to bottom!

What are your thoughts on used equipment of this type?

Certainly harder to find but perhaps the chances of getting a really good unit used is as good as the chances you take buying brand new.

Industry generally seems to buy high quality stuff because they can't afford to go cheap. A lot of this stuff hits the open market eventually. Some of it may be utterly worn out but plenty still have a lifetime of hobbyist use in them.

To me it would seem that buying a half used up Hardinge chuck would be a better route than playing Chinese roulette. Even for more money.

Maybe not, but that's my thinking anyway.

Jim, I too hope Chinese QA permeates their military industrial complex and I chuckled when I read what you wrote.

Why do you make so much sense all the time Ray??? Great stuff!

Great thread everyone.

New vs used chucks... It's just like anything else. If you know what to look for and if you know how to check it -and if it's at the right price -and if you are in the right place at the right time etc... -Whip out the wallet!

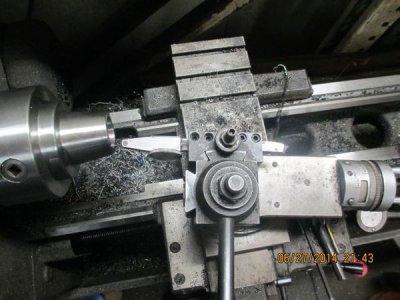

My 5C collet chuck was purchased on eBay for something like 75 bucks including shipping. It's a shars brand. The seller said it wouldn't run true. I contacted him about it and even gave him the procedure to set it up. -Nope... He was convinced it was no good and wanted no part of any discussion on how to check for sure. I bought it, set it up -and it runs dead on!

I also bought an old Union 6", 4J on eBay. The jaws were wiggling around like loose teeth in a 8 year old's mouth. I did a weld build-up on the jaw slots, re-cut new slots... -Made it a little better -but I eventually gave it away to a guy who did hobby projects with the boy scouts. -Good enough for him, not for me.

Win some, lose some...

On the flip side, most all new chucks need some dressing and fitting and every backplate I've ever had needed trimming and fine-tuning to the spindle cone.

I hate selling chucks! Some folks buy them and curse me out like crazy when they read 2 thou out. ---Did you fit the backplate and chuck? No! Well, have you got some time to hear a bedtime story about chucks?

Ray

Last edited: