I just had gears printed for a thread dial application. Thread dials carry no load and I did use nylon,.... BUT I could have ordered the gears in metal (can't remember what metal exactly it was because I knew I was going to use nylon,... Sorry I digress,... The nylon gears were about $7. each, and the same gears in metal were only about $30. so that's really not all that expensive.

If you can get the drawings for the original gears, that would be good to submit to "shapeways" if they are 3D drawings. Otherwise, you need to measure some of the parameters of the gear you are replacing and insert them into the gear design program to create .stl 3D drawings. Here's where I designed my replacement gears from measuring the original gear:

The Free STL Gear Designer For 3D Printing

www.stlgears.com

Then, because I didn't have a CAD program to view the drawings I had created with the measurements that I had made, I went to this site to view the drawings so I could make sure they matched the gears I needed. (because it would suck to make a drawing mistake and pay for gears that came out wrong)..

View 3D STL files directly in your browser - no software installation is required; Supports STL, OBJ, 3MF, VF, VSB, VSJ formats

www.viewstl.com

Then after confirming that the gears I designed matched the gears that I needed, I went to the shapeways site and looked at my options to print them. I was surprised that I could have ordered them in some kind of metal as well as have them 3D printed in a few different plastics. In my case, I ordered 2 sets of them in plastic figuring that If one set wore out quickly, I could re-order them in made in metal and still have working nylon set until the metal ones were made. Each gear cost me about $7. so with tax and shipping I spent $66. to get 6 nylon gears. When I was ordering them was when I noticed that I could have ordered them in metal for $30. each. At that point I just wanted to see what the quality would be so ordering the cheaper nylon gears made sense (cents) Here's the link to shapeways:

Shapeways is the #1 online 3D printing service company. Working with over a million customers since 2007 - Get 3D products and parts delivered to over 100 countries.

www.shapeways.com

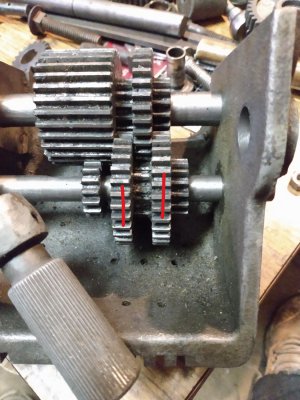

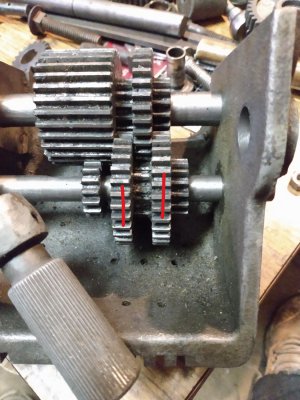

and here's a picture of what the gears I had printed look like next to the thread dial with the original metal gear that I got with the lathe (there was suppose to be 3 metal gears for that dial, but I only had 1 and the other 2 were no longer produced so, hence my need to make the other 2 sizes)

View attachment 480943