- Joined

- Jan 3, 2015

- Messages

- 400

This may be one of those dumb newbie questions, but I know this is the place to ask.

I built an oil distribution system for my G0704 conversion based on Hoss' DVD plans. (Somehow I ended up hijacking someone else's build log here. I was posting there comparing stuff and something derailed him from keeping working on it, so I just kept posting. )

I got the system debugged and running, and the mill has been sitting for a couple of weeks without running. Wednesday, I went behind the mill for something and found a puddle of oil on the floor. My oiling system has been dripping oil. To shorten this somewhat, I did everything I could think of to find where it's coming from, and eliminate sources, but I still get a couple of drops of oil every hour. It seems to be coming from the pump itself.

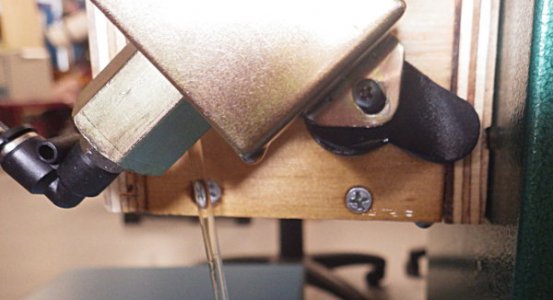

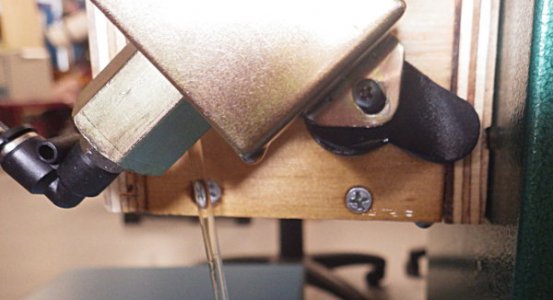

This is one of those "universal" car fuel pumps. Why? Because it's what Hoss used. Got it from an eBay auto parts seller. Low pressure (4-7 PSI), but it will pull the oil out of the bottle when the tubes are empty and pump it up onto the mill base. What I find is that when I dry everything off, the oil fittings (which are 1/8-27 NPT tapped, composite, push in fittings) are dry, but I get some oil on the frame of the pump at that bottom corner. You can see a drip on the bottom corner of the pump frame here. There's some black foam that I mounted under the pump (to reduce noise) on the right that's also getting wet with oil and ready to drip, too.

Again, the areas around the fittings are dry. The fitting on the bottom left would have a drop on it if it was leaking, and the one on the top is dry to the touch. It would probably be letting a drop run down the plastic tube to the right, but the tube's dry.

OK - newbie question time: is this normal? Does everyone's pump leak from the body of the pump? Should I get a different pump or what? Ideas?

Bob

I built an oil distribution system for my G0704 conversion based on Hoss' DVD plans. (Somehow I ended up hijacking someone else's build log here. I was posting there comparing stuff and something derailed him from keeping working on it, so I just kept posting. )

I got the system debugged and running, and the mill has been sitting for a couple of weeks without running. Wednesday, I went behind the mill for something and found a puddle of oil on the floor. My oiling system has been dripping oil. To shorten this somewhat, I did everything I could think of to find where it's coming from, and eliminate sources, but I still get a couple of drops of oil every hour. It seems to be coming from the pump itself.

This is one of those "universal" car fuel pumps. Why? Because it's what Hoss used. Got it from an eBay auto parts seller. Low pressure (4-7 PSI), but it will pull the oil out of the bottle when the tubes are empty and pump it up onto the mill base. What I find is that when I dry everything off, the oil fittings (which are 1/8-27 NPT tapped, composite, push in fittings) are dry, but I get some oil on the frame of the pump at that bottom corner. You can see a drip on the bottom corner of the pump frame here. There's some black foam that I mounted under the pump (to reduce noise) on the right that's also getting wet with oil and ready to drip, too.

Again, the areas around the fittings are dry. The fitting on the bottom left would have a drop on it if it was leaking, and the one on the top is dry to the touch. It would probably be letting a drop run down the plastic tube to the right, but the tube's dry.

OK - newbie question time: is this normal? Does everyone's pump leak from the body of the pump? Should I get a different pump or what? Ideas?

Bob