- Joined

- Dec 22, 2023

- Messages

- 49

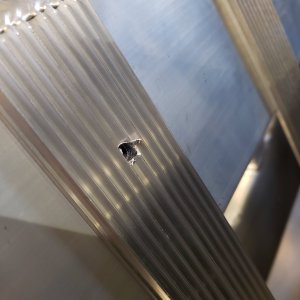

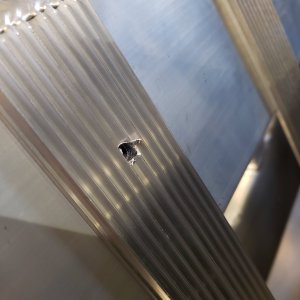

I am working on a home project making some brackets to hold some car ramps on my car trailer. I do not yet own a milling machine, and I would like to counterbore /spotface some aluminum. The OD of the counter bore would be 0.750" and the depth -.0625-0.125". Half the counterbores would be in bar stock, and the other half would be to clean up the extrusion ribs shown in the pics.

I am wondering if this is a bad idea, or could it be done in my drill press using a carbide router bit? If so, should I run the bit at the highest speed I can? Any other tips?

I am wondering if this is a bad idea, or could it be done in my drill press using a carbide router bit? If so, should I run the bit at the highest speed I can? Any other tips?