- Joined

- Jun 20, 2022

- Messages

- 215

This seems like a dumb question

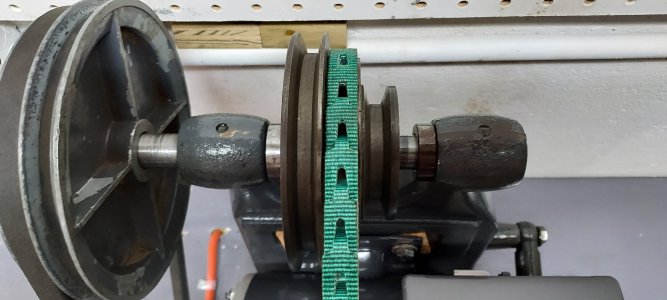

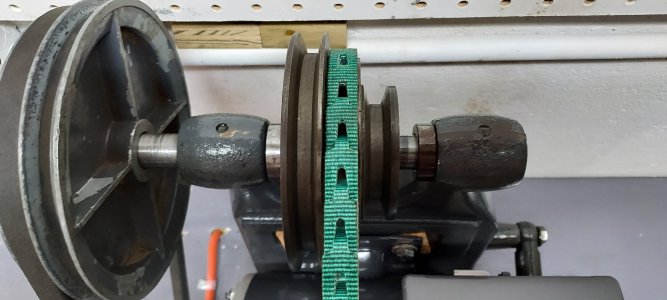

I have a "new" 1950s Logan 9B. The manual says put a drop of machine oil in the holes in the countershaft bearing supports. Ok fine.

BUT...I took this thing apart. There are NO through holes going into the shaft. These oil holes seem to hit the back of a solid bearing and end.

So I know there is such a thing as sintered bronze which liquid flows through. But I thought bearing bronze was solid? Did someone change the bearings and forget the through holes at some point? Or is the bearing material porous enough to flow oil to the shaft surface?

I have a "new" 1950s Logan 9B. The manual says put a drop of machine oil in the holes in the countershaft bearing supports. Ok fine.

BUT...I took this thing apart. There are NO through holes going into the shaft. These oil holes seem to hit the back of a solid bearing and end.

So I know there is such a thing as sintered bronze which liquid flows through. But I thought bearing bronze was solid? Did someone change the bearings and forget the through holes at some point? Or is the bearing material porous enough to flow oil to the shaft surface?