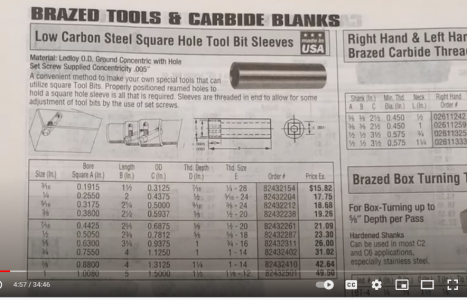

I've been trying to figure out a good way of mounting a 1/8" square tool bit through a 1" by 36" brass rod (across the 1" diameter). The bit has to be extremely square to the length of the rod. Bits would be mounted at both ends of the rod.

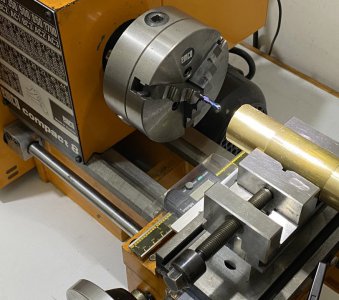

I have a tiny lathe and no mill (yet). So I don't have machines capable of holding a rod that long in a precision way. I could imagine making the ends as separate pieces, say just 2" long, so they can be worked on. But that would imply that the bulk of the rod would also need to be machined, and I can't do that.

I suppose a well-drilled hole followed by a broach would be the proper way. That feels a bit daunting.

Any other ideas?

Thank you.

I have a tiny lathe and no mill (yet). So I don't have machines capable of holding a rod that long in a precision way. I could imagine making the ends as separate pieces, say just 2" long, so they can be worked on. But that would imply that the bulk of the rod would also need to be machined, and I can't do that.

I suppose a well-drilled hole followed by a broach would be the proper way. That feels a bit daunting.

Any other ideas?

Thank you.