I just replaced my 3d printed proximity sensor mounts with aluminum. Anytime I would rehome for whatever reason I would have to re-zero the part sometimes it would be off by 5 or 6 thou. I knew it wasn't right because my router has the same setup and is repeatable to like a tenth. The issue has this disappeared with the aluminum mounts. I'm not sure if it was vibration or movement of the wires tugging them around. Something to think about.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Precision Matthews PM-728VT CNC conversion

- Thread starter koenbro

- Start date

- Joined

- Feb 23, 2016

- Messages

- 424

I just replaced my 3d printed proximity sensor mounts with aluminum. Anytime I would rehome for whatever reason I would have to re-zero the part sometimes it would be off by 5 or 6 thou. I knew it wasn't right because my router has the same setup and is repeatable to like a tenth. The issue has this disappeared with the aluminum mounts. I'm not sure if it was vibration or movement of the wires tugging them around. Something to think about.

I am very new to 3-D printing and I’m still learning about different materials. My current mounts are made out of ABS but would love to see the aluminium ones. Will you be able to post some photos?

Sent from my iPhone using Tapatalk Pro

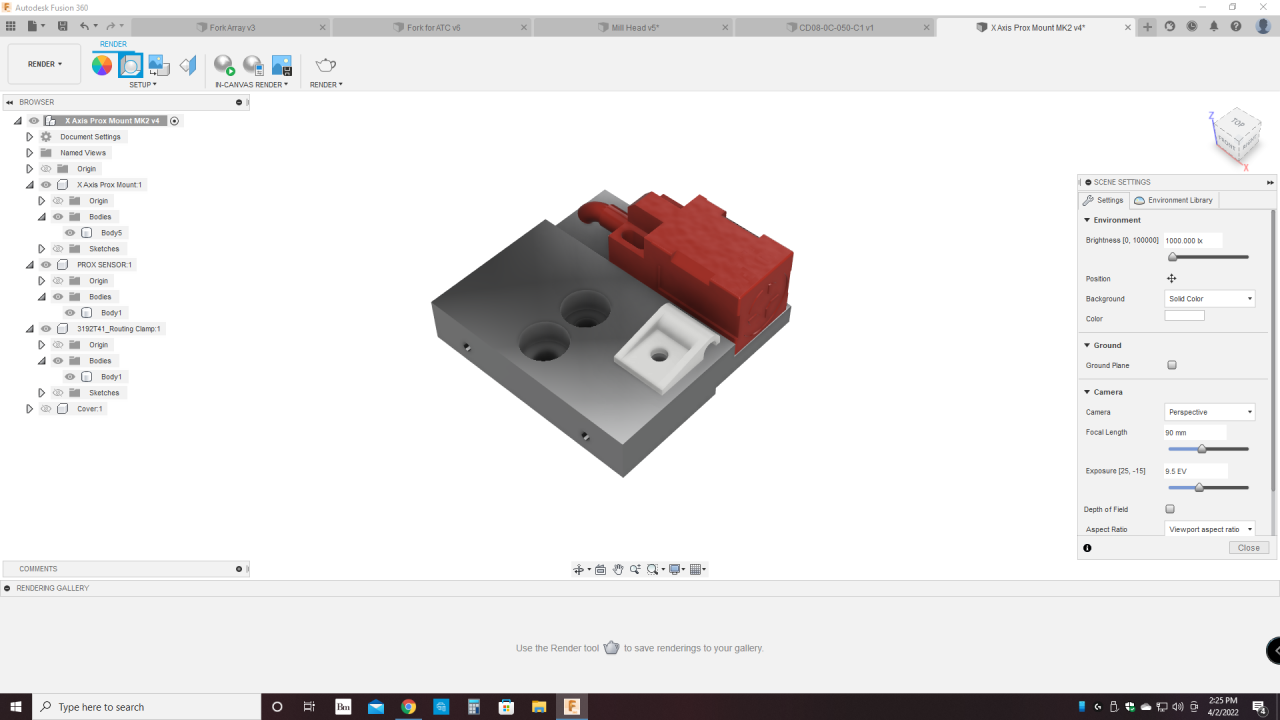

X axis mount

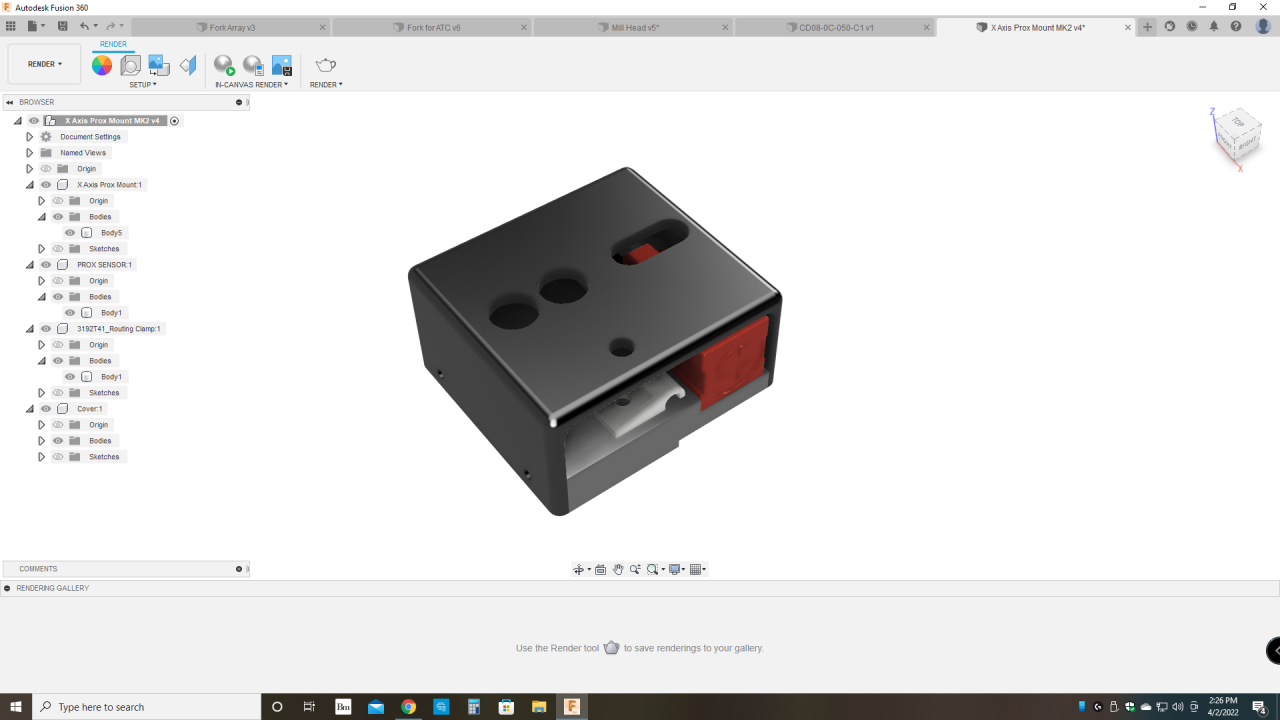

X axis with cover.

r

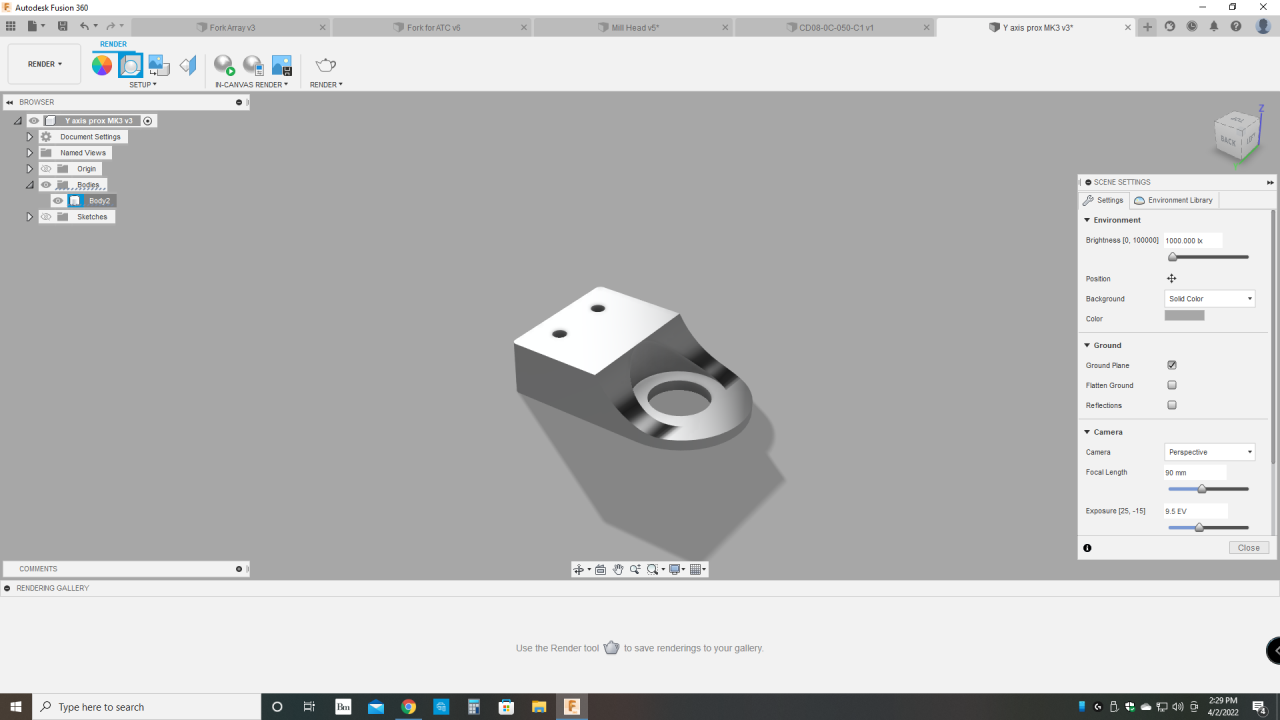

Y axis mount.

Pretty basic.

Janky printed cover, somehow "temporary" things like to stick around for a while. Currently running parts so chips everywhere.

Z axis still needs replaced but its next on the list when I get time.

X axis with cover.

r

Y axis mount.

Pretty basic.

Janky printed cover, somehow "temporary" things like to stick around for a while. Currently running parts so chips everywhere.

Z axis still needs replaced but its next on the list when I get time.

- Joined

- Feb 23, 2016

- Messages

- 424

@GB21 That looks great -- special thanks for the video. I might replace the ABS one with Alu, but first will check the repeatability you mentioned.

That said, most impressed with the toolchanger!

Would you pls share details: what controller are you using: Acorn, or some other? How did you program it?

My next step will be an ATC and expect it will be very difficult. Thanks in advance.

That said, most impressed with the toolchanger!

Would you pls share details: what controller are you using: Acorn, or some other? How did you program it?

My next step will be an ATC and expect it will be very difficult. Thanks in advance.

Last edited:

Thanks! I plan to dive into some more troubleshooting tomorrow. Made and ran the first CNC program today using the bench test config (and a scrap piece of plywood). Pretty exciting to be getting close.

Do you use your NPN sensors as both home and limit? I am starting to think about how to wire up my newly-acquired NPN sensors (same ones you have), but your inputs only show three of them. Probably a noob question, but does the machine just automatically jog in a certain direction until it hits one, and thus you have the X in series?

Do you use your NPN sensors as both home and limit? I am starting to think about how to wire up my newly-acquired NPN sensors (same ones you have), but your inputs only show three of them. Probably a noob question, but does the machine just automatically jog in a certain direction until it hits one, and thus you have the X in series?