- Joined

- Nov 21, 2012

- Messages

- 793

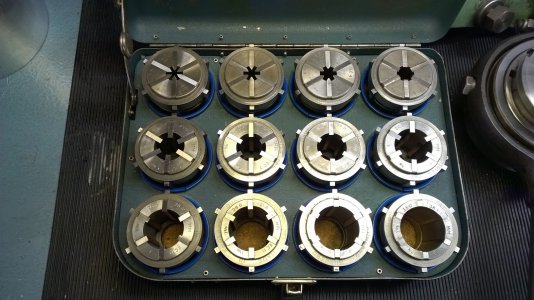

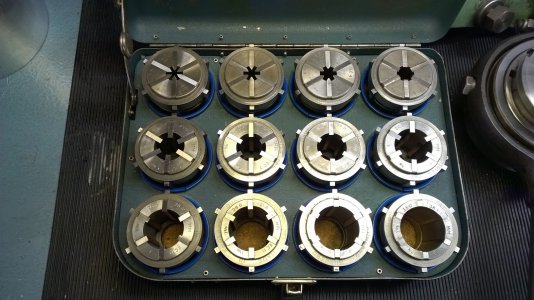

I have been on the look out for a set of collets and a collet closer for my Colchester Chippie for a while now. Last night I had 2 friends contact me within minutes of each other telling me a closer and collets had come up for sale only 45 minutes away from me for $320 USD. I rang the chap selling immediately and told him I would take them and despite the "or best offer" in his ad, I said I would take them for full price - no negotiation necessary if he would hold them for me. They looked to be in great condition:

Now you might think I am a bit silly to offer the maximum right away however these collets are a little different to most. The closest collet available to the PB collets would be the Jacobs Rubber Flex, however these are less reliable than the PB as they can become seperated between the jaws and rubber compression pads.

The PB variant does not have this problem:

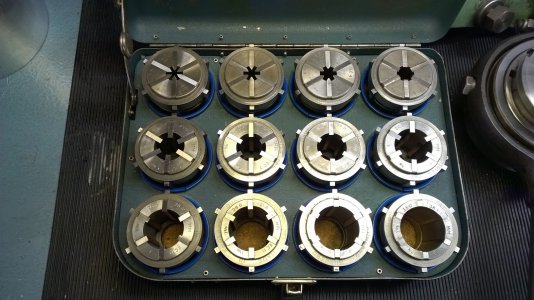

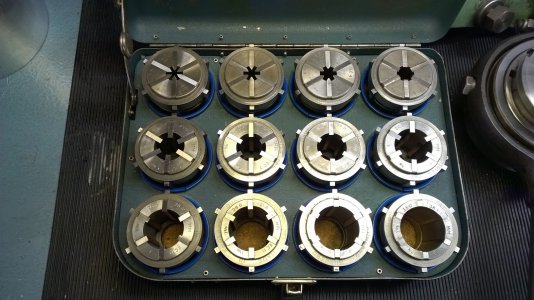

Rather than relying on rubber, the PB collets have springs to open the collet jaws. Another advantage of these collets is the wide operating range for a single collet. With only 12 collets, a range of 1.6mm to 38.1mm is covered:

The other impressive feature of these collets is that they allow the material to pass right through the collet unrestricted, all the way up to 38.1mm - which happens to be the Chipmaster's spindle bore diameter )

)

This leads me to believe that this collet set and closer was designed with the Colchester Chipmaster in mind as even the closer's handle knob is the same colour as handles found on the Chippie:

As the closer is D1-3, it marries with the Chippies spindle and takes a whole minute and a half to attach.

Overall, I couldn't be happier. They show no signs of rust, no signs of wear and for tooling made in 1966 or earlier (it was an extra accessorie following a Chippie made in 66) it is made with that old school quality mindset.

Paul.

Now you might think I am a bit silly to offer the maximum right away however these collets are a little different to most. The closest collet available to the PB collets would be the Jacobs Rubber Flex, however these are less reliable than the PB as they can become seperated between the jaws and rubber compression pads.

The PB variant does not have this problem:

Rather than relying on rubber, the PB collets have springs to open the collet jaws. Another advantage of these collets is the wide operating range for a single collet. With only 12 collets, a range of 1.6mm to 38.1mm is covered:

The other impressive feature of these collets is that they allow the material to pass right through the collet unrestricted, all the way up to 38.1mm - which happens to be the Chipmaster's spindle bore diameter

This leads me to believe that this collet set and closer was designed with the Colchester Chipmaster in mind as even the closer's handle knob is the same colour as handles found on the Chippie:

As the closer is D1-3, it marries with the Chippies spindle and takes a whole minute and a half to attach.

Overall, I couldn't be happier. They show no signs of rust, no signs of wear and for tooling made in 1966 or earlier (it was an extra accessorie following a Chippie made in 66) it is made with that old school quality mindset.

Paul.