I am engaged in a repetitive project to make eleven meat mallets, duplicating a meat mallet I made at Torrance High in a machine shop class in 1964. The first one turned out well and allowed me to learn the steps from turning the handle to milling the head. By the time I had finished making the second one, I was feeling a bit of pain in my right should from cranking the Z axis up and down for tool changes. Several videos introduced a power lift as a solution to raising and lowering the head. Quinn, Blondihacks, has a complete "How to" that convinced me a Power Lift would be a worthy investment. It would save substantial time, pain, and certainly increase my enjoyment as I work on various projects with my new Mill. This is especially true when making multiples of the same project. As my attention shifts from how, to work-flow, I prefer not to be in pain and dreading the next tool change.

This is the kit I bought. https://priesttools.com/product/power-lift-precision-matthews-pm-728vt/

This is the Blondihacks video that convinced me to order the power lift.

Before buying the kit, I called Priest Tools and spoke with Greg. He answered on the second ring as was quick to answer all my questions. He assured me this kit was well within the capabilities of someone who had limited experience with vertical mills, about 20 hours. With increased confidence, I ordered the Power Lift.

The purpose of this post is to simply share my experience installing the Power Lift on the PM-728VT. Priest Tools manufactures this kit specifically for the PM-728VT. The parts are common to a number of vertical mills. However, the precision machining of the motor plate to bolt on the top of the mill column makes this obvious. The extra holes in the plate are likely for the other mills supported by this motor plate.

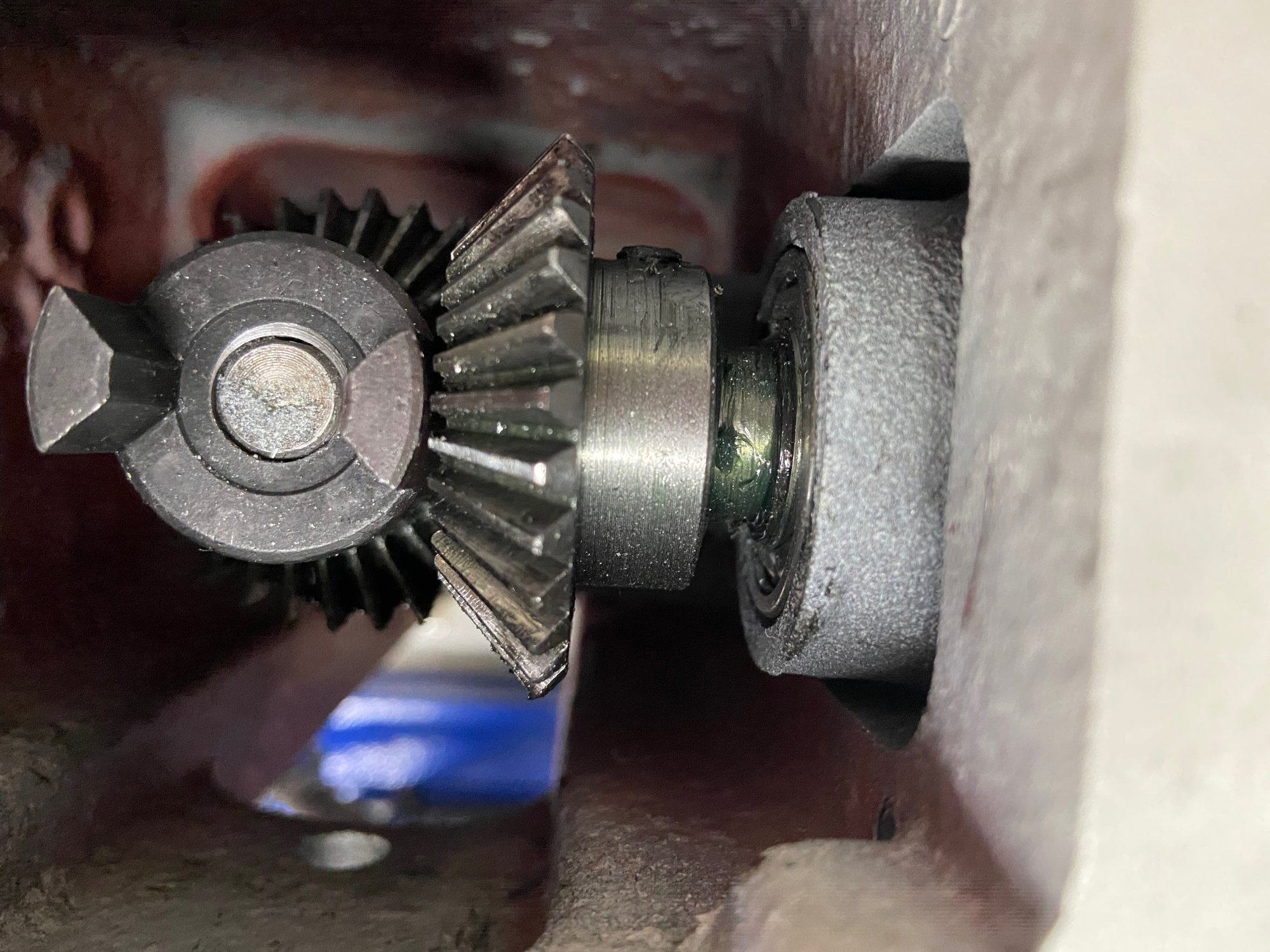

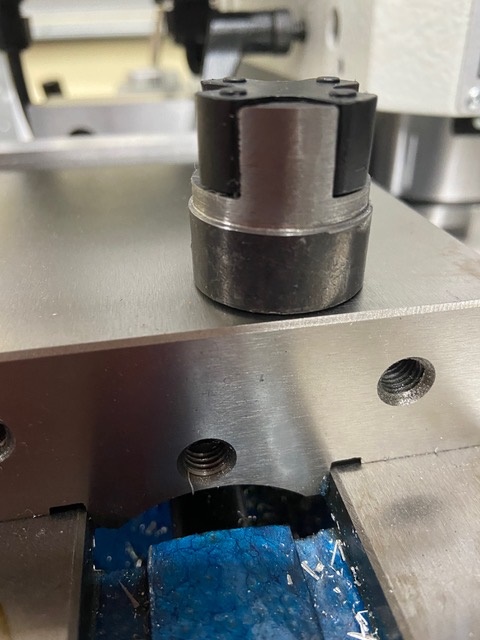

In the Power Lift PM-728VT instructions I puzzled over the instructions in item 4. "4. Note, it may be necessary to loosen the 2 set screws on the vertical bevel gear and move the gear out a bit to get clearance for the lower hub. Then tighten the set screws." I think this caution is there because the Lovejoy Hub provided with the kit fails to clear the teeth of the bevel gear.

The first image below shows one side of the Hub clearing. The second image shows the Hub striking the bevel gear. The instructions seem to address the problem by shifting the position of the bevel gear slightly to allow more clearance. I chose not to do that out of concern that would introduce more space but also backlash. Instead, I chose to turn both Hubs, the upper and the lower, down from 1.087.5 to 1.026.5 inch.

After that easy modification, all works well. To get the spacing on the motor shaft right for the lower and upper Hub, I set the upper Hub set screw snug but not tight. Then I placed the motor assembly in place and turned the hand wheel to insure all moved freely. That likely caused the upper Hub to move up the motor shaft to the proper position. Then, I removed the motor assembly and tightened the set screw, and did the final install.

I noted that Quinn, Blondihacks, chose to rely on a washer and spring washer in lieu of the set screw as recommended in the instructions.

My kit did not include washers for the Z Hub, nor was there a washer on the shaft after I removed the fiber lock nut.

I chose to use the flat place on the Z Lead Screw for the set screw, per the instructions. I modified an Allen hex wrench, shortening the short end of the “L" and used a vice grip to hold the modified Allen wrench. I took to heart the instruction's caution about being careful not to drop the nut, Hub, or tools. Thus, I was very careful not to drop anything.

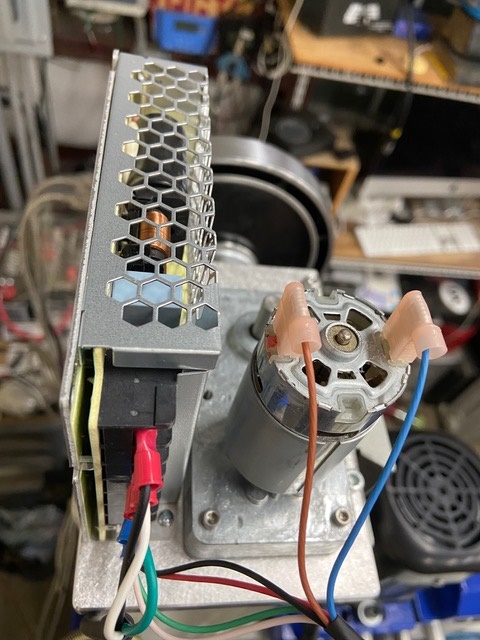

Tightening the set screw was a bit tough. There is very little room between the Hub and the side of the inside of the column. However, with the modified Allen wrench it was much easier. I turned the hand wheel a final time after bolting it all in place. Perfect, all very smooth, no binding and no noise. I then installed the power supply, completed the wiring, and installed the cover.

The first time powering the lift I noticed the up and down was reversed. I double-checked the wiring, checking to confirm the brown wire went to the red dot, and then decided to simply rotate the up/down switch to insure up moved up, and down moved down.

The Power Lift works perfectly. I highly recommend this kit. I am sure I will enjoy having the Power Lift.

Terry - W6LMJ

This is the kit I bought. https://priesttools.com/product/power-lift-precision-matthews-pm-728vt/

This is the Blondihacks video that convinced me to order the power lift.

Before buying the kit, I called Priest Tools and spoke with Greg. He answered on the second ring as was quick to answer all my questions. He assured me this kit was well within the capabilities of someone who had limited experience with vertical mills, about 20 hours. With increased confidence, I ordered the Power Lift.

The purpose of this post is to simply share my experience installing the Power Lift on the PM-728VT. Priest Tools manufactures this kit specifically for the PM-728VT. The parts are common to a number of vertical mills. However, the precision machining of the motor plate to bolt on the top of the mill column makes this obvious. The extra holes in the plate are likely for the other mills supported by this motor plate.

In the Power Lift PM-728VT instructions I puzzled over the instructions in item 4. "4. Note, it may be necessary to loosen the 2 set screws on the vertical bevel gear and move the gear out a bit to get clearance for the lower hub. Then tighten the set screws." I think this caution is there because the Lovejoy Hub provided with the kit fails to clear the teeth of the bevel gear.

The first image below shows one side of the Hub clearing. The second image shows the Hub striking the bevel gear. The instructions seem to address the problem by shifting the position of the bevel gear slightly to allow more clearance. I chose not to do that out of concern that would introduce more space but also backlash. Instead, I chose to turn both Hubs, the upper and the lower, down from 1.087.5 to 1.026.5 inch.

After that easy modification, all works well. To get the spacing on the motor shaft right for the lower and upper Hub, I set the upper Hub set screw snug but not tight. Then I placed the motor assembly in place and turned the hand wheel to insure all moved freely. That likely caused the upper Hub to move up the motor shaft to the proper position. Then, I removed the motor assembly and tightened the set screw, and did the final install.

I noted that Quinn, Blondihacks, chose to rely on a washer and spring washer in lieu of the set screw as recommended in the instructions.

My kit did not include washers for the Z Hub, nor was there a washer on the shaft after I removed the fiber lock nut.

I chose to use the flat place on the Z Lead Screw for the set screw, per the instructions. I modified an Allen hex wrench, shortening the short end of the “L" and used a vice grip to hold the modified Allen wrench. I took to heart the instruction's caution about being careful not to drop the nut, Hub, or tools. Thus, I was very careful not to drop anything.

Tightening the set screw was a bit tough. There is very little room between the Hub and the side of the inside of the column. However, with the modified Allen wrench it was much easier. I turned the hand wheel a final time after bolting it all in place. Perfect, all very smooth, no binding and no noise. I then installed the power supply, completed the wiring, and installed the cover.

The first time powering the lift I noticed the up and down was reversed. I double-checked the wiring, checking to confirm the brown wire went to the red dot, and then decided to simply rotate the up/down switch to insure up moved up, and down moved down.

The Power Lift works perfectly. I highly recommend this kit. I am sure I will enjoy having the Power Lift.

Terry - W6LMJ

Last edited: