-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Power head for my G0704 - not CNC

- Thread starter wallyw

- Start date

- Joined

- Dec 8, 2013

- Messages

- 2,651

Thank you! That is an interesting method of compounding mechanical leverage. I've not seen anything like it!

Bill

Subject to a long-expired patent, no doubt.

Note that the casting that carries the spindle is on dovetail slides on the column: that is what most of the counterweight is for.

- Joined

- Mar 21, 2013

- Messages

- 4,064

Subject to a long-expired patent, no doubt.

Note that the casting that carries the spindle is on dovetail slides on the column: that is what most of the counterweight is for.

I saw that. An interesting design. Thanks for sharing!

Bill

- Joined

- Jun 26, 2013

- Messages

- 191

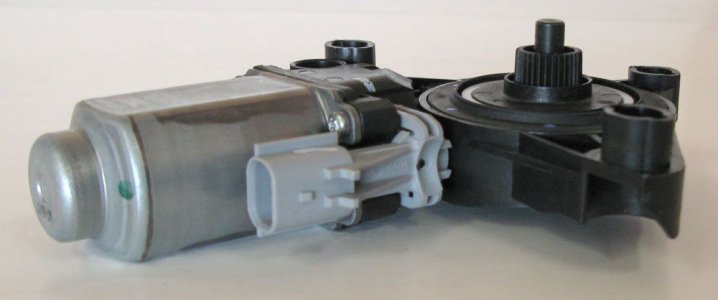

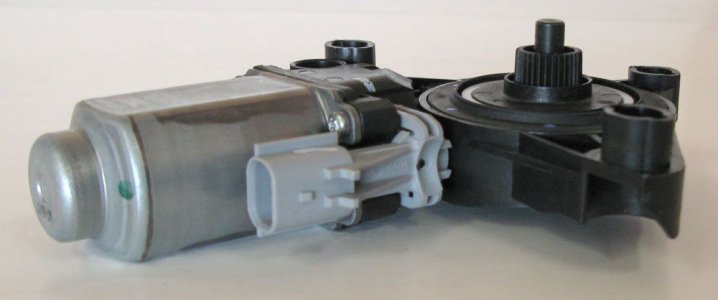

a power window motor (or cordless drill) should be more than powerful enough. The window motor would be especially useful as most already have the 90deg power take off as standard, so theoretically all you'd need to do is made a splined or hex hole in the output cog and slip that over the head crank handle shaft. I'm waving my hands around as I've never seen your mill in personThen a 12V off an old computer power supply or even a laptop charger brick if it has a high enough output, a double pole switch from radioshack and you're in business. If you can get the crank shaft to go through the motor cog, you could even reattach the hand crank and use that for when you want to go old school.

I'll have to get one of these on order and see what I can do with it...

It's hard to tell from the photo whether the output gear is metal or plastic and it doesn't look like keeping the existing crank would be an option; but they're cheap enough to be worth giving it a shot...

- Joined

- Sep 28, 2013

- Messages

- 4,317

neat! I'm sure that once you have it in your hands it will be easier to figure out how you can make it work. Let us know how it goes.

- Joined

- Jun 26, 2013

- Messages

- 191

Order placed...

I was doing some timing on how quickly I crank the handle and at 88 RPM this motor may be a bit slower than I would like. Once it shows up and I verify it has enough umph to lift the head, I may see if I can gear it back up a bit to increase the speed...

I'll report back when there's something interesting to report, but fair warning I tend to drag out projects so it may take quite a while...

I was doing some timing on how quickly I crank the handle and at 88 RPM this motor may be a bit slower than I would like. Once it shows up and I verify it has enough umph to lift the head, I may see if I can gear it back up a bit to increase the speed...

I'll report back when there's something interesting to report, but fair warning I tend to drag out projects so it may take quite a while...

- Joined

- Jun 26, 2013

- Messages

- 191

Well - bad news to report...

Once I received the motor and applied 12V to it, I realized that the 88RPM output was going to be too slow. I was thinking maybe I could use a cogged belt and pulleys to step it back up 2x or 3x in speed (with a matching drop in torque). I machined an adapter to replace the plastic splined 'gear' on the motor with something I could attach a pulley to:

Then tried my first attempt at broaching (on my lathe) to create a keyway in a shaft collar to replace the crank handle. As a first test I made a simple adapter to connect those two together so I could estimate whether the motor would have enough torque to handle a 2x or 3x reduction and still drive the shaft:

Then I gave it a try:

Unfortunately, the window lift motor doesn't have enough power to drive the shaft at all (either up or down). This was being driven from a 12Amp 12V bench supply, so I'm pretty sure that lack of input power wasn't the issue. This was disappointing, because with the built in worm gear it seemed like this motor should have been strong enough to do what I needed. Of course, without any specs it was all just guessing anyway...

For my next attempt I had read some folks suggesting the motors from cordless drills. I just happened to buy two at a hamfest last weekend for $3, so I gave one of those a try...

Similar results - not enough power from motor to lift the head. The drill motor did have enough power to lower it though.

So, anyway, it seems it's back to drawing board. I know that "Hoss" (g0704.com) was able to drive the stock z-axis lead screw from the top (vice through the crank handle gear) with a 570 oz/in stepper motor, but going with stepper motors and controllers is a bit more than I'm willing to do for this upgrade. It's not like cranking the handle is all that hard - I just thought it sounded like it would be a fun, cheap, simple mod... oh well...

I'll probably try the window motor on the x-axis shaft, just to see whether it has enough power to drive that -- that'll be academic though, because I already have a Grizzly power drive for that axis. But maybe that info will help someone else out in the future...

Once I received the motor and applied 12V to it, I realized that the 88RPM output was going to be too slow. I was thinking maybe I could use a cogged belt and pulleys to step it back up 2x or 3x in speed (with a matching drop in torque). I machined an adapter to replace the plastic splined 'gear' on the motor with something I could attach a pulley to:

Then tried my first attempt at broaching (on my lathe) to create a keyway in a shaft collar to replace the crank handle. As a first test I made a simple adapter to connect those two together so I could estimate whether the motor would have enough torque to handle a 2x or 3x reduction and still drive the shaft:

Then I gave it a try:

Unfortunately, the window lift motor doesn't have enough power to drive the shaft at all (either up or down). This was being driven from a 12Amp 12V bench supply, so I'm pretty sure that lack of input power wasn't the issue. This was disappointing, because with the built in worm gear it seemed like this motor should have been strong enough to do what I needed. Of course, without any specs it was all just guessing anyway...

For my next attempt I had read some folks suggesting the motors from cordless drills. I just happened to buy two at a hamfest last weekend for $3, so I gave one of those a try...

Similar results - not enough power from motor to lift the head. The drill motor did have enough power to lower it though.

So, anyway, it seems it's back to drawing board. I know that "Hoss" (g0704.com) was able to drive the stock z-axis lead screw from the top (vice through the crank handle gear) with a 570 oz/in stepper motor, but going with stepper motors and controllers is a bit more than I'm willing to do for this upgrade. It's not like cranking the handle is all that hard - I just thought it sounded like it would be a fun, cheap, simple mod... oh well...

I'll probably try the window motor on the x-axis shaft, just to see whether it has enough power to drive that -- that'll be academic though, because I already have a Grizzly power drive for that axis. But maybe that info will help someone else out in the future...

- Joined

- May 20, 2013

- Messages

- 390

Sorry to hear that it didn't work - sure seemed like it might. I know most of the drives I've seen do away with the gear at the top and drive the lead screw direct, so maybe that is a clue.

- Joined

- Sep 28, 2013

- Messages

- 4,317

likewise, I thought that it would work  Well, at least you gave it a shot. Do you have a rough idea how much the head weighs? That might give folks an idea what sort of head/ table weights these motors can handle.

Well, at least you gave it a shot. Do you have a rough idea how much the head weighs? That might give folks an idea what sort of head/ table weights these motors can handle.