-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Oct 7, 2020

- Messages

- 2,113

Wow! Nice job on the center caps, they look great!

- Joined

- Nov 26, 2015

- Messages

- 4,773

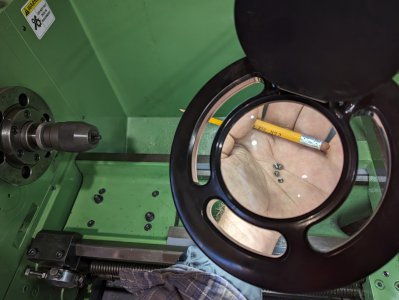

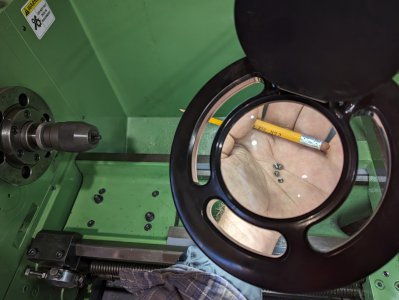

As the paint was drying on the HBM, I made some money on a Sunday afternoon. Turning some brake drums for a repeat customer. These are off of his gooseneck trailer. Replace drums are almost $400 dollars apiece because the hub is integrated into the drum. Seeing he would need 4 of them I said I would help him out. They weigh 60 pounds and are just over 12" in diameter.

- Joined

- Apr 23, 2018

- Messages

- 6,532

Small parts...

A friend picked up a cheap RIA slide to try the optics division with his double-stack 1911. I made the RMRc cut, and these are the recoil lugs. I plan to stay with iron sights until I'm blind and toothless, but he wanted to see what the fuss was about. He's a high A-class shooter who stands a good chance at sweeping the field, so why not. 70% of competitors are using optics now, it's really changing the sport.

A friend picked up a cheap RIA slide to try the optics division with his double-stack 1911. I made the RMRc cut, and these are the recoil lugs. I plan to stay with iron sights until I'm blind and toothless, but he wanted to see what the fuss was about. He's a high A-class shooter who stands a good chance at sweeping the field, so why not. 70% of competitors are using optics now, it's really changing the sport.

- Joined

- Sep 2, 2013

- Messages

- 5,100

Had to repair the the tie rod for the MF tractor. After trying PB and heat to get the tie rod end out I had cut a slice in the tie rod, and even then it was a 36" pipe wrench, and a 6' cheater. Ordered a m24x1.5 tap from e-bay to clean up the threads, and ended up having dress the end of the tap with a cutoff wheel to get it to start. Got the tap run all the way in, and the new TR end now screwed in nicely. Vee'd out the slice I had made in the tie rod, and welded it up, being careful not to mess up the internal threads. May have been ok like that, but decided a little reinforcement would be good insurance. Cut a chunk off an old Harley fork tube, and bored it to a tight slip fit over the tie rod, sliced a section out of the patch that lined up with the welded slice in the tie rod and welded it up along with both ends of the patch. Cleaned it up with a flap disc, and a done deal. Mike

- Joined

- Oct 7, 2020

- Messages

- 2,113

Good job on making the battery box and the welding clamp. It's fun to make stuff like that.I don't know how you can make this for 6.00 but I have 12 dollars and love making stuff so why not View attachment 484019

Tig welding is the easiest way to weld if your not a welder..

View attachment 484020

View attachment 484022

View attachment 484023

View attachment 484024

Battery rack for my 24 yz250x using a DeWalt 12v battery for a fan because I ride really rocky ST and will overheat the yz in no time.

Love that I have the tools to make anything I need but love the men that believed in me enoughto show me how to use them... if you have a daughter don't forget her we can do this stuff too..

Where did you get that cool welding fixture table?