I took the pressure off the head, completely loosened the lower gib screw and then tightened the top gib screw until it the screw got tight then backed it off half a turn. It binds on both the upper part and lower part of the column. So, i am loosing a few inches on travel already at both the top and bottom. How can i tell for sure?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM727M DILEMMA

- Thread starter Brad125

- Start date

- Joined

- Sep 28, 2013

- Messages

- 4,318

sounds like a Friday afternoon special. I would negotiate with PM about returning it for a replacement. Binding at either extreme of travel usually indicates noticeable wear in the middle, which can't be the case here as it's new. You're starting to get into the realm of accurately mapping out the column dovetail and that's really more work than you should be doing for a machine under warranty.

Mattthemuppet2, did you see the video?sounds like a Friday afternoon special. I would negotiate with PM about returning it for a replacement. Binding at either extreme of travel usually indicates noticeable wear in the middle, which can't be the case here as it's new. You're starting to get into the realm of accurately mapping out the column dovetail and that's really more work than you should be doing for a machine under warranty.

- Joined

- Sep 28, 2013

- Messages

- 4,318

yes, that's an awful lot of movement. As David wrote, a few thou is normal (my knee is ~0.002", my quill is ~0.001), but 30 thou is way off. Without any other information I would said "that's a crazy loose gib", but you've already said the gib is tight.

Only other suggestion is to repeat the test with the gib tightened as you wrote in post #51 at the top, middle and bottom of the travel. If the head is binding at either extreme, then you should see a much smaller distance between locked and unlocked at the ends compared with the middle. If that turns out to be the case, then your column dovetails are not parallel but "wasted" in the middle.

Another quick Q - do the dovetails have way oil (or some kind of oil) on them? Just another thing to check.

Only other suggestion is to repeat the test with the gib tightened as you wrote in post #51 at the top, middle and bottom of the travel. If the head is binding at either extreme, then you should see a much smaller distance between locked and unlocked at the ends compared with the middle. If that turns out to be the case, then your column dovetails are not parallel but "wasted" in the middle.

Another quick Q - do the dovetails have way oil (or some kind of oil) on them? Just another thing to check.

yes, that's an awful lot of movement. As David wrote, a few thou is normal (my knee is ~0.002", my quill is ~0.001), but 30 thou is way off. Without any other information I would said "that's a crazy loose gib", but you've already said the gib is tight.

Only other suggestion is to repeat the test with the gib tightened as you wrote in post #51 at the top, middle and bottom of the travel. If the head is binding at either extreme, then you should see a much smaller distance between locked and unlocked at the ends compared with the middle. If that turns out to be the case, then your column dovetails are not parallel but "wasted" in the middle.

Another quick Q - do the dovetails have way oil (or some kind of oil) on them? Just another thing to check.

Yes i use sae 30, cause its the only thing i can find locally. It is alway very well lubed and well taken care of. I am always wiping it down and cleaning it.

- Joined

- Jun 26, 2018

- Messages

- 1,733

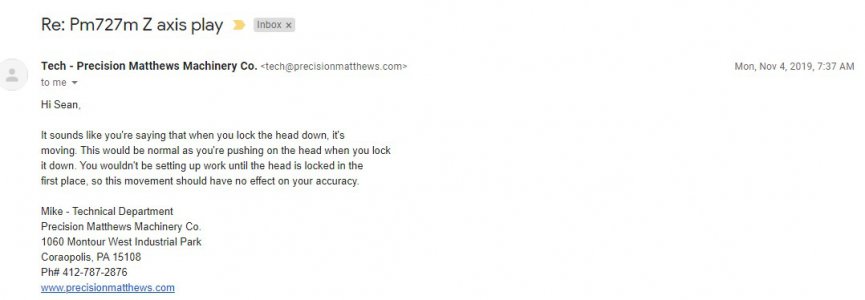

I posted my reply here I got from PM for the same exact situation (as your video). Ultimately they say no matter if you cutting or calibrating, it will be locked, so the movement is of no matter. You tighten on gob lock and it goes one way, tighten the other and it comes back around, once you tighten both they don't equal zero, but where ever they end up, your going to calibrate that compensation in. This is what I was told. I will also say, I gave my Z gibs adjusted to where I am happy with them. I truly believe you will get no fix for this from PM, at least I don't know why you would get a different answer than I received.

Attachments

- Joined

- Sep 28, 2013

- Messages

- 4,318

that's pretty shonky. So do you have a specific gib tightening order, as the OP showed a variation in movement depending on which gib was locked? I'd want to be really sure that whenever I reposition the head I can get it to lock up in exactly the same position relative to the table.

And that doesn't deal with the OP's issue of the head binding at the top and bottom of the travel when the gib is tightened properly.

Hopefully PM will sort this out, otherwise I struggle to see how anyone could recommend this mill.

And that doesn't deal with the OP's issue of the head binding at the top and bottom of the travel when the gib is tightened properly.

Hopefully PM will sort this out, otherwise I struggle to see how anyone could recommend this mill.

Exactly, dont forget the colums needs 0.025 thousandths of shims to be square. I mean, dont get me wrong, i am not expecting super high precision, but when you can not even move the head up and atleast maintain reasonable positioning the something is wrong, especially when it is out this far. I am not bashing PM as i have stated before, i like there products and quality. I honestly believe I recieved on that was out of spec. I read somewhere else that Matt checks one every so often, so, atleast he tries to assure his standards are met. This one just slipped thru the cracks. It happens, its todays manufacturing techniques. However, i am sure if Matt seen this himself, he would agree that something is wrong and would make the situation right. I mean these machines cost alot of money, atleast to me they do. So, when i invest that much money into a machine i want to know its right, or atleast know i will be taken care of. Thats why I bought from PM cause of there reputation for both customer servise and support.

- Joined

- Jun 26, 2018

- Messages

- 1,733

Well, I hope it's not stalling until a certain amount of time passes. You live close? I understand moving from basement is not easy, perhaps remove column, take it in and have them exchange it. Is that the problem? With the tight then loose gibs and the inconsistency depending where the head is located vertically...maybe. I don't know what the best versus easiest answer is, but I'm watching this thread for sure.