- Joined

- Jul 3, 2015

- Messages

- 144

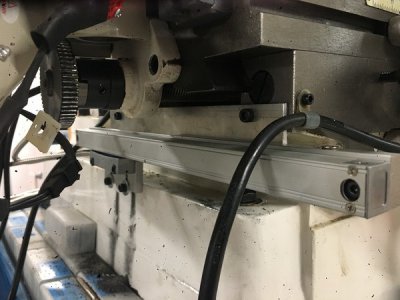

Here are a couple of photos of the PM Matthews DRO install for my PM-932 mill that I did this weekend. I couldn't find much for photos that showed mounting brackets when I was looking for info so I thought posting these may be of some help to others. I wanted to have both read heads fixed and the rails move. Seemed to me to be the best way as there is very little cable movement that could potentially cause problems. The kit came with several angle brackets that didn't seem to be usable for much, the only one I used was a single flat plate. For the others I used 3/8" plate aluminium. (I just happened to have a bin of scrap 3/8" aluminium plate). The plate thickness needed some adjusting so as to locate the read head correctly. All the mounting holes are slotted for adjustability. As I could no longer use the stock accordion chip cover I decided to use it's two existing tapped holes to mount the read head plate on the back of the table. I also used the chip cover's rear holes to hold a rubber flap as a chip cover. The bracket design made it very easy to adjust the read head vertically. Now I just need to figure out how to use all the features of the DRO.