I called PM support and they walked me through taking the spindle apart so I can loosen the bearings. I haven't done so yet, but they agreed they are probably just a tad too tight. The guy on the phone said it's a fine balance between too loose where you have spindle runout, and too tight where you have excessive friction/heat.Was wondering if you dug deeper into the spindle heat issue on your 833?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-833TV and PM-1340GT Delivery Today

- Thread starter cday2021

- Start date

Hi David,Hey Craig,

Glad you got it all up an running. You might want to check out what I did for the DRO install on the 1340. I wanted the magnetic scales on the X and Z pointing face down, and also wanted to integrate a drag-chain into the setup for the cabling and Fogbuster air/coolant supply to the cross slide. It's all documented here, including how I dealt with the carriage locking screw. Now that I've had it in use for four years, I'm thankful I took a little extra time to get the DRO mounted the way it is.

Mark pointed me to your flickr album... some very splendid work you do. Extremely impressive. Thanks for the links to the DRO install. Great solution too. Are there any drawbacks to Mark's install with the lock on the headstock side and having it conflict with the follower rest?

cheers,

Craig

Congratulations Craig.

I know we would love to see your new machine tools set up in your shop. Pics please.

You mentioned, this is the first time running a lathe.

Please be aware, you have a gear head lathe. They are not forgiving when it comes to their operation. They are powerful machines.

Please be aware of the lathe safety rules.

There are plenty of videos on Youtube.

Have fun and be careful.

Thanks for the safety tips. Great video. I've been a woodworker for 25+ years and have a shop full of tools that are ready to eat me alive, but the video was a great reminder to keep safe. The shirt into the lead screw would have been alarming! A good reminder to keep loose clothing out of the shop.

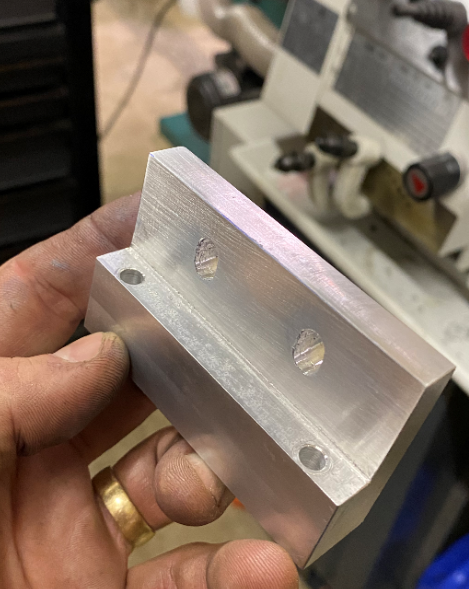

Update #2 -- the DRO is now installed on the lathe. The cross slide was straight forward. I installed the other scale on the backside of the machine. I had to machine two brackets to bring the scale further away from the machine and to act as a mounting point for the cover. I machined a 3rd bracket to use with the two supplied brackets to mount the sensor head to the back of the carriage. I reused the bolt holes in the back of the carriage that are meant for the taper attachment for the PM-1340GT.

(without the cover installed)

(without the cover installed)

I'm going to do what Mark did on his cross slide. See the following link:How are we dealing with the cross slide locking bolt under the DRO scale?

https://www.hobby-machinist.com/threads/erl-1340-cross-slide-lock-for-dro-equipped-lathes.78854/

- Joined

- Mar 23, 2021

- Messages

- 357

Congrats on your new machines Craig!

I'm wondering if you got the stand for your 1340GT from PM? If you did, I have a favor to ask as I have a 1340GT on order and would like to get some things done in advance.

I will be raising the lathe since I'm 6'1" and don't want to be stooping while working the hand wheels for hours while machining.

Could you tell me what the distance is from the base of the stand (no feet/levelers included) to the spindle center as well as the distance from the base to the center of the carriage hand wheel?

I contacted tech support at PM today, but they don't have the measurements.

Thanks!

Jake

I'm wondering if you got the stand for your 1340GT from PM? If you did, I have a favor to ask as I have a 1340GT on order and would like to get some things done in advance.

I will be raising the lathe since I'm 6'1" and don't want to be stooping while working the hand wheels for hours while machining.

Could you tell me what the distance is from the base of the stand (no feet/levelers included) to the spindle center as well as the distance from the base to the center of the carriage hand wheel?

I contacted tech support at PM today, but they don't have the measurements.

Thanks!

Jake