- Joined

- Nov 23, 2014

- Messages

- 2,607

Oh, I thought you just really, really, really liked the machine!Nice looking machine! Appreciate the detailed view into the delivery and vise.

Welcome to the forum

Sent from my iPhone using Tapatalk

Bruce

Oh, I thought you just really, really, really liked the machine!Nice looking machine! Appreciate the detailed view into the delivery and vise.

Welcome to the forum

Sent from my iPhone using Tapatalk

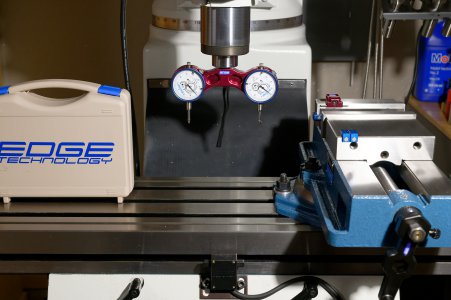

I'm working with PM right now. There is a short punch list...have a belt/noise issue that the factory is working on. I'll recap at the other end. The X,Y,Z controls feel like buttah. Power is really good - the back gear makes this a torque monster for steel. Ran a face mill on some aluminum plate and surface finish was excellent. Having a power feed on the Z (this is a heavy Z) is..well...can't imagine cranking by hand. Lots to like.Checking in to see if you had much opportunity to use the mill? I would like to hear some feedback on it?? How does the controls feel?? How does the fit and feel of the machine?? Noise level?? Vibration??