-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Picked up a couple vices at an estate sale.

- Thread starter ebgb68

- Start date

4

4GSR

Forum Guest

Register Today

Thank you 4gsr for the help. Once the tilt vise is done I'm starting on the regular vise. I have it trammed in and dont want to move it till another vise is ready. I'm really wondering what if has for marking underneath.

ebgb68,

I'll take and flip mine over if I get a chance today and verify what's on bottom. I'll take a picture and post.

Ken

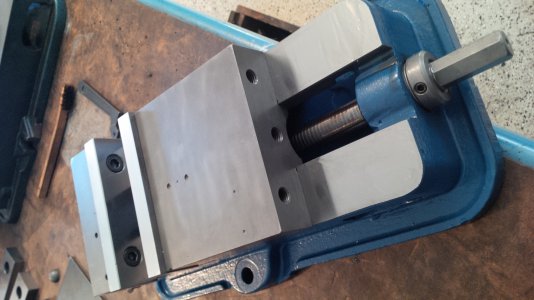

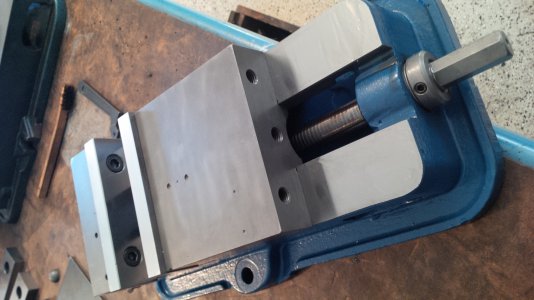

Looking good. Yes, I'd like to see the bottom of the Yuasa also. Good to know how to ID one if one of us come across one for sale in the future. This is what a bottom of a Kurt D60 looks like. I ground the jaws, and the bottom then top of the vise. Only had to take a few thousands off total. Put it back together with a Kurt rebuild kit. Put some fresh oil on it and it feels and indicates in like new.

Looking good. Yes, I'd like to see the bottom of the Yuasa also. Good to know how to ID one if one of us come across one for sale in the future. This is what a bottom of a Kurt D60 looks like. I ground the jaws, and the bottom then top of the vise. Only had to take a few thousands off total. Put it back together with a Kurt rebuild kit. Put some fresh oil on it and it feels and indicates in like new.

Last edited:

I rebuilt a Kurt D675 right after the D60. Would like to stick both of them on the Okamoto at the same time and grind to match. But they don't quite fit on the magnet at the same time. Will be getting a used 8 inch Kurt for the new mill. Plan on rebuilding and grinding same as the other two.

- Joined

- May 4, 2015

- Messages

- 3,583

You did well and on the repair also. I was going to suggest the same thing or a thread sert, or helicoil repair. But ya did the same as the thread serts with your bolt and redrill an tap. I like the hammered gray paint . Good job , a little heat and you can bend the crank part back.

Look closely at the fit and finish of mating part.

If the hole in mating part is rough cast you can clean it up and drill tap stripped hole to next larger size maybe fine thread.

Thread insert maybe but simple re thread is simple fix that could im] rove fit and finish when done

If the hole in mating part is rough cast you can clean it up and drill tap stripped hole to next larger size maybe fine thread.

Thread insert maybe but simple re thread is simple fix that could im] rove fit and finish when done

- Joined

- May 25, 2016

- Messages

- 181

Question: I picked up an older (but not in bad shape) D60, and I'm looking at the D60 rebuild kit available from Kurt. My D60 uses a collar to retain the screw, but the D60 kit ships with a spring retainer. Also, the D60 kit ships with 3 thrust washers, and I only see two on the vise. Is the 3rd one supposed to go between the casting and the front retaining collar? Sadly, the D60 is the ONLY vise kurt doesn't have the exploded diagram on their website! Any insight would be appreciated!