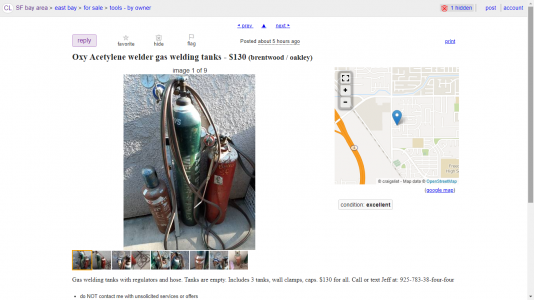

My “basics” list for building my first home shop was OA, bench grinder, arc welder, horizontal bandsaw. OA is the most versatile because you can weld, braze, solder, cut and heat with the same rig. Now I only have one of the small rigs because I have a plasma and don’t need the huge tanks to cut with. For the first 20yrs I was making my Tone-Gard for all kinds of acoustic instruments they were all hand formed and OA welded. This is a one off custom for a cello player who stands with the cello supported by a strap. He played in the WVU bluegrass band.